Mashiinka Ballaarinta Jiifka ah ee 6 Tube

Nidaamka isku-xidhka

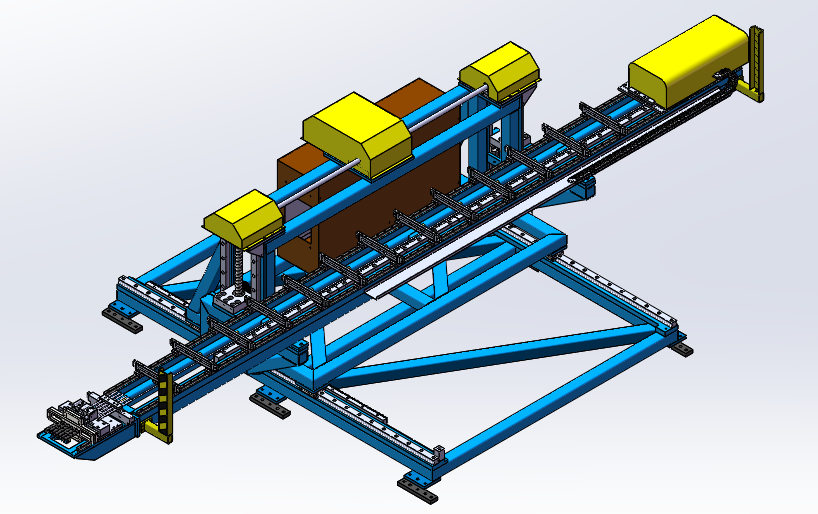

1. Cabbirka mashiinka: 8500mm * 3800mm * 1400mm

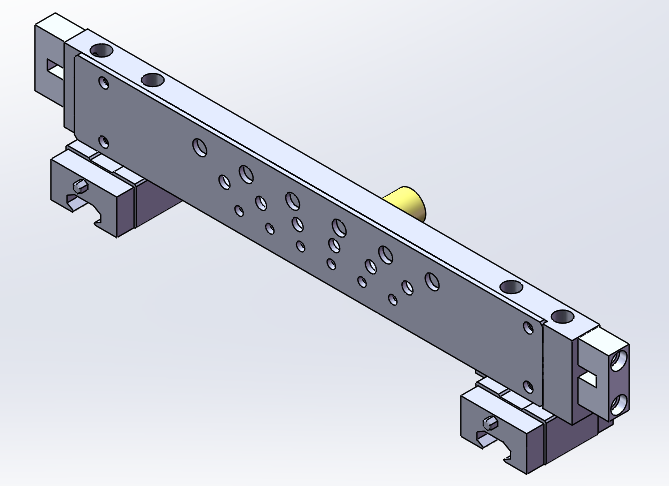

Habka hagaha baarka ballaarinta

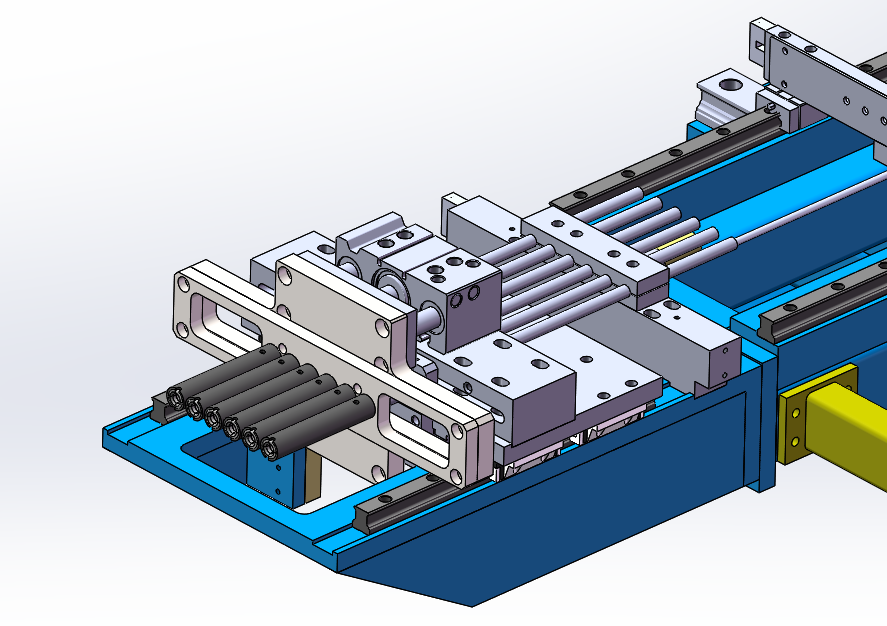

Nidaamka Qabsashada Pneumatic

farsamada wadista ballaarinta

3. Saddex nooc oo godad hagitaan ah oo leh masaafo dhexe oo kala duwan ayaa lagu diyaariyey saxanka hagaha si loo fududeeyo beddelka qeexitaannada.

4. Matoorka Servo wuxuu wadaa rack iyo gear si uu u wado baarka ballaarinta hore iyo gadaal.

5. Qaadista mashiinka waxaa wada wiishka giraangiraha ee gooryaanka waxaana maamula nidaamka servo. Waxay samayn kartaa tuubo ballaaran oo leh garaaca ugu badan ee qaadista oo ah 400 mm.

6. Mashiinka waxaa lagu rakibay saxanka hagaha wuxuuna si toosan u socon karaa iyadoo masaafada dhaqaaqu ay tahay 2700 mm.

7. Qalabku wuxuu bixiyaa laba qaab oo hawlgal ah: habka gacanta iyo habka semi-automatic.

(1) Habka gacanta lagu qaato: Tallaabo kasta waa hawlgal gacanta lagu sameeyo.

(2) Habka Semi-otomaatigga ah: si buuxda otomaatig ah u shaqeynta habka ballaarinta tuubada, badhanka hawlgalka gacanta ee afka iswaafajinta, turjumaadda isdhaafsiga iyo kor u qaadista iyadoo loo eegayo masaafada la dejiyay.

8. Ballaariyaha Haydarooliga ama qalabka gacanta lagu qodo: Ballaarinta dekedda tuubada naxaasta ah ka hor inta aan la balaarin tuubada si loogu diyaariyo balaadhinta tuubada.

9. Sababtoo ah heerka kala duwan ee hoos u dhaca U-tube, waxay sababi doontaa tuubooyin dhaadheer iyo kuwo gaaban ka dib marka la ballaariyo, sidaa darteed mashiinku ma ballaarin karo U-tube.

10. Qalabka waxaa ku shaqeeya shaashadda taabashada waxaana maamula PLC.

6 Mashiinka Ballaarinta Jiifka ah ee Tuubada; Mashiinka Ballaarinta Jiifka ah; Mashiinka Mashiinka Cadaadiska ah ee Aluminium; Mashiinka Ballaarinta Jiifka ah; Mashiinka Ballaarinta Jiifka ah; Mashiinka Ballaarinta Jiifka ah; Mashiinka Ballaarinta Jiifka ah ee Tuubada; Qalabka Ballaarinta Jiifka ah ee Tuubada; Qalabka Ballaarinta Jiifka ah ee Tuubada; Qalabka Ballaarinta Jiifka ah ee Tuubada; Qalabka Ballaarinta Jiifka ah ee Tuubada; Mashiinka Ballaarinta Jiifka ah ee OMS

Qaylo-dhaan sax ah oo biibiile ballaarinaya: 400-4000mm

Dhexroorka Tuubada: 3/8" iyo 1/2"

Cabbirka tuubada siman:φ3/8” x 21.65 +1/2”X31.75

Tirada Tuubooyinka: 8 tuubo

Xawaaraha balaadhinta tuubada: 13M/daqiiqo (xawaare degdeg ah) 13m/daqiiqo (soo celin)

Awoodda matoorka: 2-5KW, 380V, 50Hz

| No | Shay | Summada |

| 1 | PLC | Mitsubishi(Japan) |

| 2 | Nidaamka Adeegga | Mitsubishi (Japan) ama Estun |

| 3 | Shaashadda Taabashada | Weinview |

| 4 | Silsilad iyo waalka solenoid | Adeko (Taiwan), SMC (Japan), CKD (Japan) |

| 5 | Beddelka iyo dareemaha u dhowaanshaha | Omron (Japan), Otonix (Kuuriyada) |

| 6 | Qalabka Korontada ee Furan iyo kan Hoose | Schneider, Omron, Siemens, Panasonic |

| No | Shay | Tirada | Cutubka | Moodel | Calaamad |

| 1 | Qalabka | 1 | dejisan | ||

| 2 | rasaas | Kumbiyuutarrada | Lix xabbo oo cabbirkiiba ah | Ku dar mashiinka | |

| 3 | Baloogga Ballaarinta | 10 | Kumbiyuutarrada | Lix xabbo cabbirkiiba | Ku dar mashiinka |

| 4 | Beddelka u dhowaanshaha | 4 | Kumbiyuutarrada | ||

| 5 | Badhan | 2 | Kumbiyuutarrada |