CNC Fiber Laser Machine Goynta

EFC3015 CNC mashiinka goynta laser waxaa inta badan loo isticmaalaa goynta saxan siman iyo ka baaraandegidda, iyada oo loo marayo nidaamka CNC, line toosan iyo qalooca qaab sabab la'aan ah la gooyn karaa oo xardhay in saxanka. Waxay si ku habboon u gooyn kartaa saxanadda birta kaarboon ee caadiga ah, saxan bir ah, saxan naxaas ah, naxaas jaale ah iyo aluminium, iyo biraha kale ee aan si fudud loo jari karin habka wax-qabadka caadiga ah.

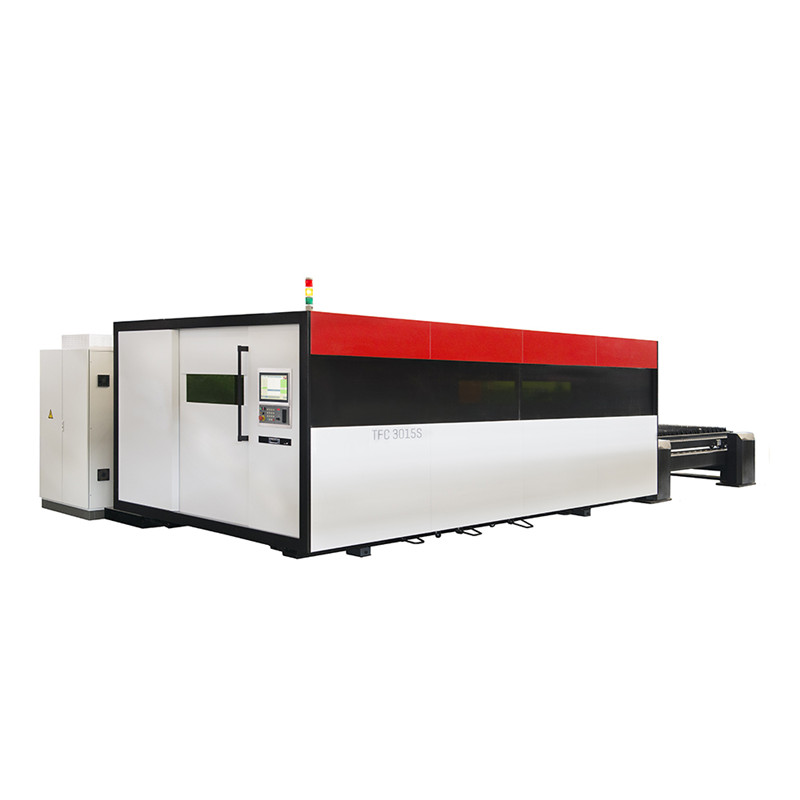

EFC3015 CNC mashiinka goynta laser waa nooc cusub oo mashiinka goynta laysarka. Qaabdhismeedku wuxuu leeyahay qallafsanaan sare, xasillooni wanaagsan, wax ku oolnimada goynta sare iyo saxnaanta mashiinnada sare. Alaabooyinku waa dabacsanaan sare, badbaado, hawlgal sahlan iyo isticmaalka tamarta yar. Waxay ka tirsan tahay alaabta ilaalinta deegaanka, cabbirka saxanka la warshadeeyay: 3000 * 1500mm; oo leh gaashaanka badbaadada iyo miiska shuttle. Qaabka guud waa mid kooban oo macquul ah.

Isticmaalka hooseeya - laser uma baahna gaas;

Isticmaalka tamarta hooseeya, tamarta tamarta, ilaalinta deegaanka, isticmaalka tamarta hoose;

Qaab dhismeedka qaab-dhismeedka, nidaamka qaboojinta iyo nidaamka isha iftiinka iyo isha laysarka ayaa isku dhafan;

Xasiloonida sare - awoodda - nidaamka xakamaynta jawaab celinta waqtiga oo leh awoodda laser, xasilloonida awoodda 1%;

Kharashaadka dayactirku waa yar yahay - madaxa fiber-ka oo isticmaalaya tignoolajiyada ilaalinta muraayadda, haddii ay wasakhoobaan, kaliya waxay u baahan yihiin in la beddelo muraayadda ilaalinta;

A. Waxay qabataa hage toosan oo sax ah oo dibadda laga keeno, soo dejiso saxan saxan oo marsho ah, hubi saxnaanta meelaynta iyo soo celinta.

B. Nooca Gantry dual motor qaab dhismeedka tooska ah ayaa ka dhigaya dhammaan qaab dhismeedka alaabadu inay yihiin kuwo is haysta, qallafsanaantuna waa wanaagsan tahay, dhererka mashiinka oo dhanna wuu hooseeyaa.

Jirka ugu weyn waxaa lagu welded taarikada birta ah, ka dib mashiinada qallafsan, la tacaalida walaaca gabowga gariir. Iyada oo loo marayo makiinad sax ah, waxay bixisaa madal adag iyo heerka nidaamka dhaqdhaqaaqa.

Dhuxulku waxay qabataa qaab-dhismeed dabacsan, oo leh balaadhinta kulaylka la-qabsiga iyo shaqada foosha, xisaabinta iyada oo loo marayo habka curiyaha xaddidan. Qaybaha looxa waxa lagu rakibaa sariirta iyadoo la raacayo hage toosan oo toosan. Hagaha, qalabka iyo raakishka waxaa lagu qalabeeyay dabool difaac oo dabacsan, si looga fogaado in ay wasakhoobaan.

Alaabtu waxay ku qalabaysan tahay miiska shaqada, fududahay in la raro lana dejiyo marka la jarayo. Hoosta miiska shaqada ee ku qalabaysan qaybo qaybsan boorka iyo jeexdin alaabta ururinaysa, oo ku habboon gaadhiga taayirrada, qashinka ayaa si toos ah u geli kara baabuurka qashinka.

Laser Fiber waxa uu leeyahay sifooyinka u dhow infrared spectroscopy, tayada alwaax kaamil ah, gudbinta fiber indhaha, hufnaan beddelka electro-optical sare iyo wixii la mid ah.

(1) Laydhka cas ee iftiinka laysarka ee shaqada.

(2) Wax ku oolnimada beddelka elektro-optic-ga sare: Fiber laser electro-optic waxtarka beddelka waa qiyaastii 33%.

(3) Isha bamka laysarka ee fiber-ka ayaa ka samaysan awood sare oo halbeeg ah oo halbeeg ah, iyo celceliska wakhtiga guuldarada waa ka yar yahay.

(4) Waxtarka sare, walxaha kuleylka gudaha waa mid aad u hooseeya marka loo eego laser-dhaqameedka, baahida korontada iyo qaboojinta si weyn ayaa loo dhimay.

(5) Koronto-dhaliyaha laysarka uma baahna gaas shaqeynaya, gudaha lens-ka ayaa ku yaal oo uma baahna in la ilaaliyo, uma baahna waqtiga bilowga

(1) Nidaamka xakamaynta CNC wuxuu adeegsadaa nidaamka Windows 7, waxqabadku waa mid deggan oo la isku halayn karo.

(2) Hirarka weyn ee AC dhijitaalka ah servo motor si loo hubiyo in saxnaanta meelaynta alaabta iyo waxqabadka firfircoon.

(3) Jilidda garaafyada.

(4) Shaqada xakamaynta korantada.

(5) Shaqada boodboodka.

(6) Goynta shaqada iskaanka.

(7) Shaqada farsamaynta fiiqan.

(8) Jooji shaqada, waxay si toos ah u diiwaangelisaa qaybta habraaca.

(9) Dib-u-eegistii barnaamijka NC waa la beddeli karaa wakhtiga dhabta ah si wax looga beddelo habka tafatirka.

(10) Wax ka beddel, wax ka beddel tilmaamaha habka barnaamijka raadinta si aad u...

(11) shaqada is-ogaanshaha, ka reeban alaarmiga ayaa lagu soo bandhigay interface-ka hawlgalka.

(12) Cabirka qalabka shaqada waa la kordhin karaa waana la dhimi karaa.

(13) Hawsha habaynta sawirka ee workpiece.

(14) Shaqo raadinta cidhifeedka tooska ah.

(15) Dabka ka dib, isku-duwayaasha hadda waa la duubi karaa oo si toos ah dib ayaa loo dejin karaa ka dib marka korontadu shido.

Laydhka laysarka waxa uu ka samaysan yahay fibre indhaha, laydhka laysarkana waxa uu la mid yahay muraayada diirada la saarayo. Muraayadaha difaaca ee lagu rakibay kursiga muraayadda "nooca jiid", dayactirka iyo waqtiga beddelka waa mid aad u gaaban. Dooro madaxa goynta laysarka oo leh dareeraha korantada ee aan la xiriirin, waxqabadka waa mid deggan oo la isku halleyn karo, fududahay in la isticmaalo.

Tilmaamuhu waa sida soo socota:

(1) Isticmaalka muraayadaha ilaalinta nooca khaanadaha si loo fududeeyo beddelka degdegga ah ee muraayadaha ilaalinta indhaha ee ilaalinta lenska collimator iyo lenska diiradda saaraya.

(2) Madaxa goynta waxaa ku qalabaysan dhererka dhidibka Z si toos ah qalabka dabagalka kaas oo ay gacanta ku hayaan shidma awood aan xidhiidh lahayn. Habka goynta, booska qaraabo ee u dhexeeya diiradda laser iyo saxanka si toos ah ayaa loo hagaajin karaa masaafada u dhaxaysa dusha sare ee workpiece iyo nozzle.

(3) Madaxa goynta laysarka wuxuu ku siin karaa nidaamka CNC calaamadda furitaanka fiilada iyo goynta madaxa, iwm.

(4) Cadaadiska gaaska ee 2.5 MPa waxaa lagu soo rogi karaa jarista qalabka wax lagu sameeyo sida birta aan fiicnayn.

(5) Biyo qabow, jarista gaasta kaaliyaha ah, dareemayaasha, iwm ayaa dhamaantood isku dhafan madaxa goynta, si wax ku ool ah u yareeya dhaawaca qaybaha kore ee habka goynta, hagaajinta xasiloonida alaabta.

4.Aalad badbaado:

Goobta wax lagu farsameeyo waxa lagu xidhay dabool difaac ah waxaana la siiyay daaqad ilaalin badbaado ah si ay hawlwadeenada uga ilaaliso shucaaca laysarka.

5.Ururinta siigada:

Meesha la jarayo waxaa lagu qalabeeyaa tuubo nuugid siigo, iyo boodh centrifugal xoog leh ayaa loo isticmaalaa si looga saaro boodhka iyo boodhka. Bixi hawada hawada iyo cabbirka is-dhexgalka iyo tuubada 3 mitir, tuubada fidinta waxaa sameeyay isticmaaluhu iyadoo loo eegayo goobta, dhererka tuubada dabayshu waxay ka yar tahay mitirka 10, hawada hawada ka baxsan;

6.Awoodda ka hortagga faragelinta:

Nidaamka xakamaynta dhijitaalka ah ee horumarsan, wuxuu awood u leeyahay inuu iska caabiyo faragelinta. Nidaamka korantada wuxuu si adag u qaataa naqshadaynta xakamaynta, golaha kontoroolka korantada wuxuu u qaybsan yahay gobollo xoog leh oo daciif ah, taas oo si wax ku ool ah uga hortagi karta faragelinta wadajirka ah ee qaybaha korantada, si ay u hubiso in la isku halleyn karo oo xasilloon ee alaabta.

7. Iftiin:

Aagga goynta waxaa lagu qalabeeyay laba nalal oo danab badbaado leh, kuwaas oo bixin kara iftiinka marka iftiinku ku filnaado ama la dayactiro, taas oo ka dhigaysa hawlgalka mid ku habboon.

8. Qaybaha korantada:

Qaybaha korantada ee isticmaalaya Schneider iyo badeecadaha kale ee caanka ah ee shirkadda Brand Company, oo si weyn u wanaajinaya kalsoonida hawlgalka. Golaha korantada wuxuu qaataa qaab dhismeedka madaxa banaan ee xiran, iyo midabka siliga waxaa loo isticmaalaa in lagu kala saaro AC, DC, awoodda iyo siliga dhulka ilaalinta.

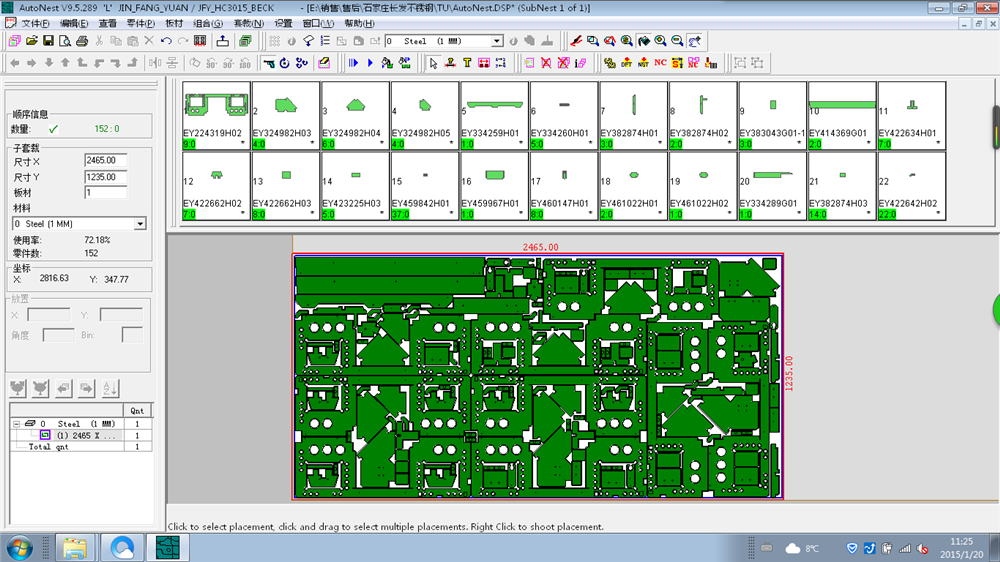

Alaabada ku qalabaysan software-ka tooska ah ee CNCKAD, ma aha oo kaliya in lagu xidhi karo farsamada CAD / CAM ee warshadda, laakiin sidoo kale si loo yareeyo culeyska shaqada ee barnaamijyada iyo suurtagalnimada qaladka, barnaamijka wanaagsan wuxuu u ekaan karaa goynta. Ku qalabaysan qaabka goynta qaabaynta, si toos ah u wanaajiya iyo qaabaynta qaybaha la samaynayo. Labada garaafyada workpiece fudud oo adag si toos ah ayaa loo rogi karaa barnaamijka processing.

Habka goynta laser NC function software barnaamijyada:

(1) Isku xirka hawlgalka Shiinaha oo dhan.

(2) Taageerada DWG, galinta DXF iyo qaababka wax soo saarka.

(3) Waxqabadka is-hubinta waa wanaagsan yahay, diido in la sameeyo hawlgalka qaladka

(4) Shaqada buulka tooska ah, wax badbaadinaya.

(5) Shaqo goynta lakabyo badan oo si toos ah oo toos ah.

(6) Hawsha xardho.

(7) Faro kala duwan oo loogu talagalay UK iyo Shiinaha.

(8) Dhererka qaabka goynta waa la xisaabin karaa.

(9) Shaqada goynta cidhifyada guud.

(10) Hawlaha maaraynta kharashka.

(11) Goynta xog-ururinta

(12) Isweydaarsiga xogta waxaa lagu sameyn karaa USB ama RS232 interface.

* Deegaanka ka hawlgala software (ku tali isticmaalaha inuu taageero qalabka)

(1) Xusuusta 256M

(2) Hard Drive 80G

(3) Nidaamka hawlgalka Windows XP

(4) TFT 17 "LCD bandhigay

(5) 16X DVD CD-ROM

| Shayga | Qty. | Xusuusin/Qayb-qeybiye |

| Nidaamka CNC | 1 set | Beck Hoff |

| Wadid | 1 set | LUST Drive( dhidibka X/Y)+ mooto PHASE( dhidibka X/Y) |

| Koronto dhaliyaha leysarka | 1 set | TRUFIBER GOOR |

| X/Y dhidibka saxda ah | 1 set | GUDEL/ATLANTA/GAMBANI |

| dhidibka Z kubbadda saxda ah | 1 set | THK |

| X/Y/Z dhidibka saxda ah ee kubbadda toosan | 1 set | THK |

| Matoor loogu talagalay miiska shuttle | 1 set | SEW |

| Qaybaha pneumatic | 1 set | SMC, GENTEC |

| Madaxa Goynta | 1 set | PRECITEC |

| Software-ka otomaatiga ah | 1 set | CNCKAD |

| Qaybaha korantada | 1 set | Schneider |

| Towline | 1 set | IGUS |

| Biyo qaboojiye | 1 set | TONGFEI |

| Maya | Shayga | Tilmaamid | Unug |

| 1 | Awood | 380/50 | V/Hz |

| 2 | Awood qaybinta loo baahan yahay | 40 | kVA |

| 3 | Xasiloonida Awoodda | ± 10% | |

| 4 | Kombiyuutarka | RAM 256M / Hard disk 80G, DVD | |

| 5 | Ogsajiinta jarista birta kaarboonka | Nadiifnimadu waa inay ka sarraysaa 99.9% | |

| 6 | Nitrojiin loogu talagalay jarista birta aan lahayn | Nadiifnimadu waa inay ka sarraysaa 99.9% | |

| 7 | Biyaha biyaha qaboojiyaha (biyo la miiray) | 100 | L |

| Waxqabadka:>25μS/cm | μs | ||

| 8 | Biyo saafi ah | 150 | L |

| 9 | Iska caabin dhuleed | ≤4 | Ω |

| 10 | Rakibaadda heerkulka deegaanka ee koronto-dhaliyaha laysarka | 5-40 | ℃ |

| 11 | Rakibaadda qoyaanka deegaanka ee koronto-dhaliyaha laysarka | In ka yar 70% | |

| 12 | Shuruuda meesha lagu rakibo (faahfaahinta waxaa loo tixraaci karaa sawirka aasaaska) | Dhumucda la taaban karo ee aasaasiga ah waa inay ka sii dhumuc weyn tahay 250mm, fidsanaanta waa inay ka yaraataa 10mm 3m kasta. Waa inuusan jirin gariir gudaha aagga rakibaadda. | |

| Shayga | Qty. | Unug |

| muraayad difaac | 5 | PC |

| giraanta dhoobada | 1 | Maya |

| Goynta birta | 6 | Maya |

| Spanner | 1 | Maya |

Bixi dhammaan dukumentiyada farsamada ee lagama maarmaanka ah oo faahfaahsan si loogu rakibo, hawlgalka iyo dayactirka

(1) Tilmaamaha Mashiinnada Goynta Laser-ka

(2) Xogta Nidaamka CNC

(3) Jaantuska mabda'a korantada

(4) Tilmaamaha qaboojiyeyaasha biyaha

(5) Qaabka Rakibaadda

(6) Sawirka aasaaska

(7) Shahaadada Aqoonta

(8) Rakibaadda, hawlgelinta iyo aqbalaadda

Ka dib markii ay alaabtu timaado goobta rakibaadda isticmaalaha, shirkadeena waxay diyaarin doontaa shaqaale khibrad leh goobta isticmaalaha si loo rakibo, loo diro loona gooyo muunada iyo habaynta. Aqbalaada kama dambaysta ah waxaa lagu fuliyaa goobta isticmaalaha iyadoo loo eegayo heerka aqbalaadda shirkadeena. Waxyaabaha la aqbali karo waxaa ka mid ah: tayada muuqaalka, qaabeynta qayb kasta, goynta saxnaanta iyo tayada, cabbirrada waxqabadka, xasilloonida, imtixaanka shaqada, iwm.

Shirkaddayadu waxay mas'uul ka tahay rakibidda iyo hawlgelinta . Isticmaalayaashu waxay u baahan yihiin inay diyaariyaan awoodda loo baahan yahay iyo alaabta kor u qaadista. Isticmaalayaashu waxay diyaariyaan agabka la isticmaalo iyo alaabta muunada ah ee hawsha.

Talaabada koowaad

(1) Aqbalaada hordhaca ah ee alaabta waxaa lagu fuliyaa shirkadeena.

(2) Aqbalaada alaabooyinka waa in lagu fuliyaa si waafaqsan heshiiska farsamo ee ay saxiixeen labada dhinac.

(3) Kormeerka muuqaalka alaabta: qaabka dhuumaha waa inuu ahaadaa mid macquul ah, nadiif ah oo qurux badan, isku xirnaan la isku halayn karo; lebbiska dusha rinji iyo qurxinta quruxda badan; muuqaalka sheyga oo aan garaacin iyo cillado kale.

(4) Kormeerka qaabeynta alaabta.

(5) Kormeerka goobta ee goynta tayada muunadda.

Tallaabada 2 Ogolaanshaha

(1) Aqbalaada kama dambaysta ah ee alaabta waxaa lagu fuliyaa goobta isticmaalaha.

(2) Aqbalaada alaabada waa in lagu fuliyaa si waafaqsan heshiiska farsamo ee la saxeexay iyo amarka wareejinta aqbalaadda, agabka tijaabada waa in uu bixiyaa adeegsadaha. Haddii isticmaaluhu u baahan yahay inuu aqbalo sawirada caadiga ah ee shaqada, fadlan horay u sii sawirada caadiga ah (nooca elektarooniga ah).

(3) Ka dib marka la dhammeeyo rakibidda iyo hawlgelinta, haddii alaabtu si caadi ah u socoto, waxay gudbi doontaa imtixaanka aqbalaadda. Imtixaanka aqbalida kama dambaysta ah waxa loo tixgalin doonaa mid u qalma oo wakhtiga dammaanadda tayada ayaa bilaabmaya.

(1) Looga baahan yahay ardaydu inay haystaan dugsi sare ama waxbarasho sare (khakhasuska korantada ayaa ah kan ugu fiican), isla markaana, yaqaana aqoonta aasaasiga ah ee kombuyuutarka, oo ay xirfad u leeyihiin shaqada kombiyuutarka.

(2) Ka dib rakibidda iyo hawlgelinta, shirkadeena waxay mas'uul ka tahay bixinta tababar bilaash ah oo loogu talagalay isticmaalayaasha 7 maalmood, tababarka 1 shaqaalaha dayactirka korontada, 2 hawlwadeen iyo 1 shaqaale dayactirka farsamada ah. Oo hubi in hawlwadeenada adeegsadaha ay asal ahaan si fiican u garan karaan waxqabadka badeecada, hawlgalka saxda ah iyo xirfadaha dayactirka.

(3) Waxyaabaha ku jira tababarka: qaab-dhismeedka sheyga iyo waxqabadka, waxqabadka laser, hawlgalka, barnaamijka NC, tignoolajiyada farsamaynta laser, dayactirka maalinlaha ah iyo dhinacyo kale.

(4) Taageerada tababbarka gaarka ah: Isticmaalayaashu waxay diyaarin karaan 2-3 hawlwadeeno iyo shaqaale dayactir ah inay yimaadaan shirkaddayada wakhti kasta.

Tababarka waa laga dhaafay khidmadaha tababarka.

Kharashyada ku baxa muddada dammaanadda waxaa bixin doona shirkaddayada, marka laga reebo kuwa ku kacay isticmaalka khaldan iyo hawlgalka isticmaalayaashu.

Shirkadeena waxay bixisaa adeegyada dayactirka iyo agabka nolosha.

Muddada dammaanadda tayada alaabadu waa hal sano, muddada dammaanadda tayada muraayadda indhahana waa 90 maalmood. Goynta birta, goynta saxanadda iliga taageerta, curiyaha shaandhada, jidhka dhoobada iyo muraayadaha indhaha ayaa ah qaybo si fudud loo jebiyo.

Fiiro gaar ah: EFC waxay leedahay shaqo jarista hawada (10kg kombaresarka hawada), laakiin macmiilku waa inuu qalabeeyaa qaybaha soo socda keligiis.

CNC Fiber Laser Machine Goynta Mashiinka Goynta Fiber Laser; CNC Fiber laser Goynta

| Shayga | Magaca | Summada | Qaabka | OTY |

| 1 | Compressor hawada aan saliid lahayn | WW-0.9/1.0 | 1 | |

| 2 | Qalajiyaha | PARKER | SPL012 | 1 |

| 3 | Kala soocida biyaha | domnick | WS020CBFX | 1 |

| 4 | Shaandhayso | domnick | AO015CBFX | 1 |

| 5 | Shaandhayso | domnick | AA015CBFX | 1 |

| 6 | Shaandhayso | domnick | ACS015CBMX | 1 |

| 7 | Isku-xidhka | PARKER | FXKE2 | 2 |

| 8 | Isku-xidhka | PARKER | NJ015LG | 1 |

| 9 | Cadaadiska cadaadiska | FESTO | LR-1/2-D-MIDI | 1 |

| 10 | Wadajir | SMC | KQ2H12-04AS | 1 |

| 11 | Wadajir | SMC | KQ2L12-04AS | 6 |

| 12 | Wadajir | SMC | KQ2P-12 | 1 |

| 13 | Dhuumaha gaasta | SMC | T1209B | 15m |

| 14 | Wadajir | EMB | VADKO 15-RL/WD | 1 |

| 15 | Wadajir | EMB | X A15-RL/WD | 1 |

1. Tilmaamaha ugu weyn

| Shayga | Tilmaamid | Unug | |

| 1 | Cabbirka Goynta xaashida | 3000×1500 | mm |

| 2 | Dhidibka X | 3000 | mm |

| 3 | Faaliga Y dhidibka | 1500 | mm |

| 4 | Faaliga Z Axis | 280 | mm |

| 5 | Max. Xawaaraha quudinta | 140 | m/min |

| 6 | Saxnimada Goynta | ±0.1 | mm/m |

| 7 | Laysarka Laysku qiimeeyay | 1000 | W |

| 8 | Dhumucda goynta (marka shuruudaha goynta loo baahan yahay la buuxiyo) | Birta Kaarboon 0.5-12 | mm |

| Birta Aan Lahayn 0.5-5 | mm | ||

| 9 | Dhumucda Goynta Deggan | Birta Kaarboon 10 | mm |

| Biraha Aan Lahayn 4 | mm | ||

| 10 | Awoodda wax-gelinta | 31 | kVA |

| 11 | Wakhtiga beddelka miiska shuttle | 10 | S |

| 12 | Miisaanka mashiinka | 8 | t |

2.SPI Laser Resonator

| Qaabka | TruFiber -1000 |

| Awoodda wax-gelinta | 3000W |

| Awoodda wax soo saarka | 1000W |

| Xasiloonida Korontada Laser-ka | <1% |

| Dhererka hirarka leysarka | 1075nm |

3.Nidaamka CNC

| Shayga | Tilmaamid |

| nidaamka CNC | Beckhoff |

| Processor | Dual-core 1.9 GHz |

| Awoodda nidaamka xusuusta | 4GB |

| Awoodda xusuusta qalabka | 8GB |

| Muuji nooca shaashadda & cabbirka | 19 ″ midab crystal dareere ah |

| Dekadda isgaarsiinta caadiga ah | USB2.0, Ethernet |