Tayada Sare ee CNC Press Fargeeska

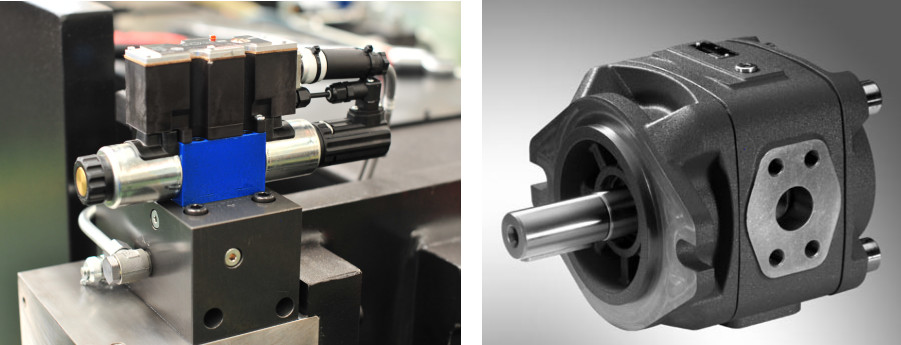

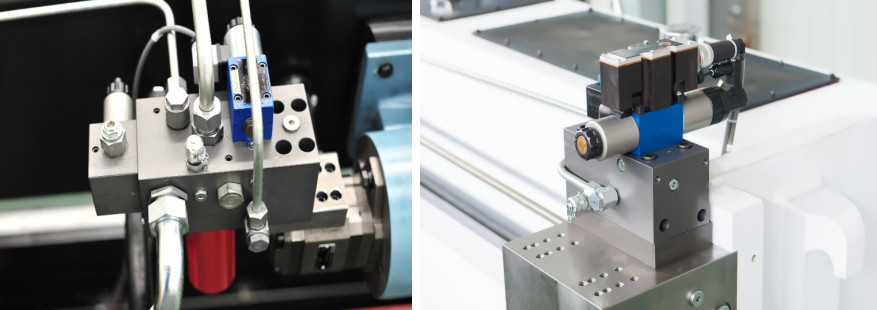

1.Electro-hydraulic system waxaa loo qaataa in lagu xakameeyo laba-siligoos si loo helo saxnaanta kontoroolka isku dhafan, saxnaanta foorarsiga sare, iyo dib u habeynta saxnaanta.

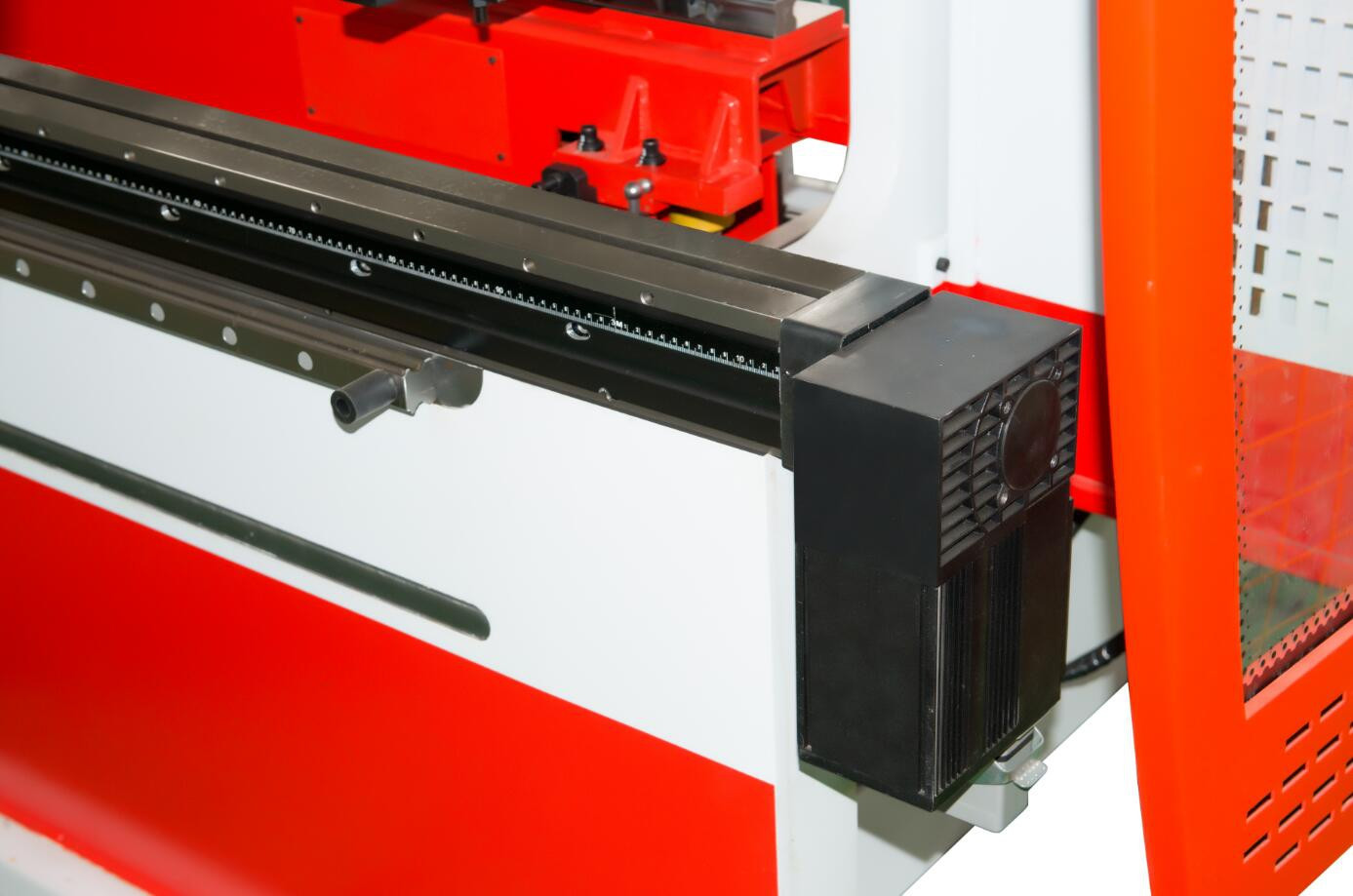

2. Qalabaynta farsamada ee nidaamka magdhowga tooska ah ayaa loo qaatay si loo xalliyo saameynta qallafsanaanta slider inta lagu jiro habka foorarsiga tayada shaqada. Qadarka magdhowga waxaa si toos ah u hagaajiya nidaamka CNC si loo fududeeyo saxnaanta.

(1) Mashiinka waxaa lagu magdhabaa qaab-dhismeed laba-dhinac ah, kaas oo ku qancin kara magdhowga jihada leexinta iyo dhererka ee mashiinka.

(2) Habka magdhowga dhibcaha cufan ayaa la qaatay si saxnaanta foorarsiga looga dhigo mid sax ah.

(3) foorarsiga ee magdhow ah dhumucdiisuna saxan isku mid ah hal mar, ka duwan ka magdhow Haydarooliga iyo dib iyo dib u dhaqdhaqaaqa qaab-dhismeedka, magdhow farsamo si weyn u yaraynaysaa qalabka workbench daal deformation, hagaajinaysaa ay nolosha adeeg;

(4) Isticmaal dhimis gaar ah iyo potentiometer sax ah oo sarreeya si aad si sax ah u xakamayso saxnaanta magdhowga.

(5) Ka duwan qaab dhismeedka saddex-taarikada ee hydraulic magdhow worktable, qalab this qaata design worktable hal-taxan, kaas oo wax ku ool ah ka hortagi kara faragelinta qaloocin workpiece.

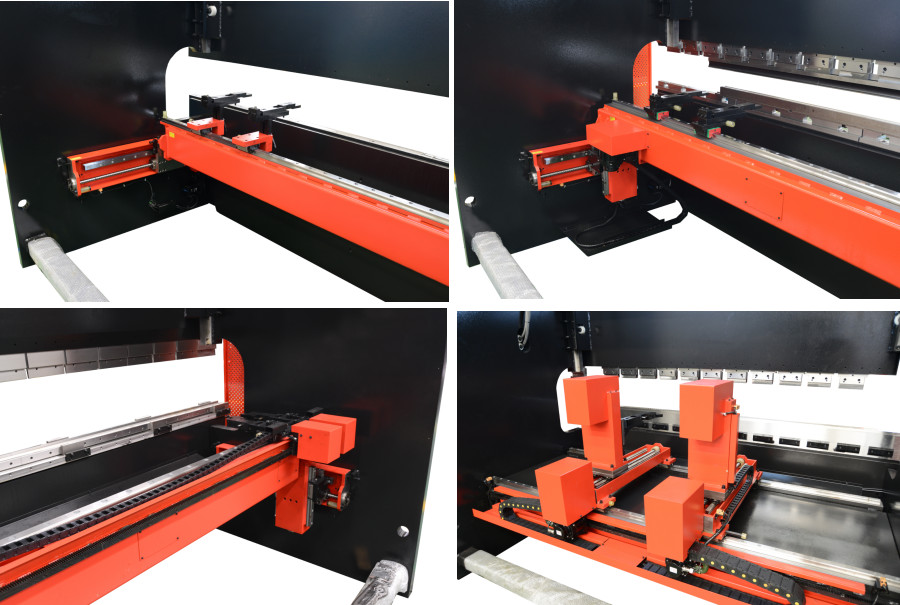

3. Qalabka dhabarka ee Multi-functional kaas oo loo kordhin karo 6 faas, sida, X1 iyo X2 faashash gadaal iyo gadaal, R1 iyo R2 faashash kor iyo hoos iyo Z1 iyo Z2 bidix iyo midig. Qallooca shaqada waxaa lagu xaqiijin karaa dabacsanaan.

4. Jirka waxaa la soo ururiyey hal mar alxanka ka dib, waxaa lagu farsameeyaa xarunta CNC pentahedron processing, hubinta qallafsanaanta iyo habaynta saxnaanta ee jir ah.

5. Nidaamka xakamaynta haydarooliga ee isku dhafan ayaa hoos u dhigaya dhuumaha, sidaas awgeed waxay ka fogaataa daadinta saliidda waxayna hagaajinaysaa xasilloonida waxqabadka, sidoo kale muuqaalka mashiinka ayaa la qurxiyaa.

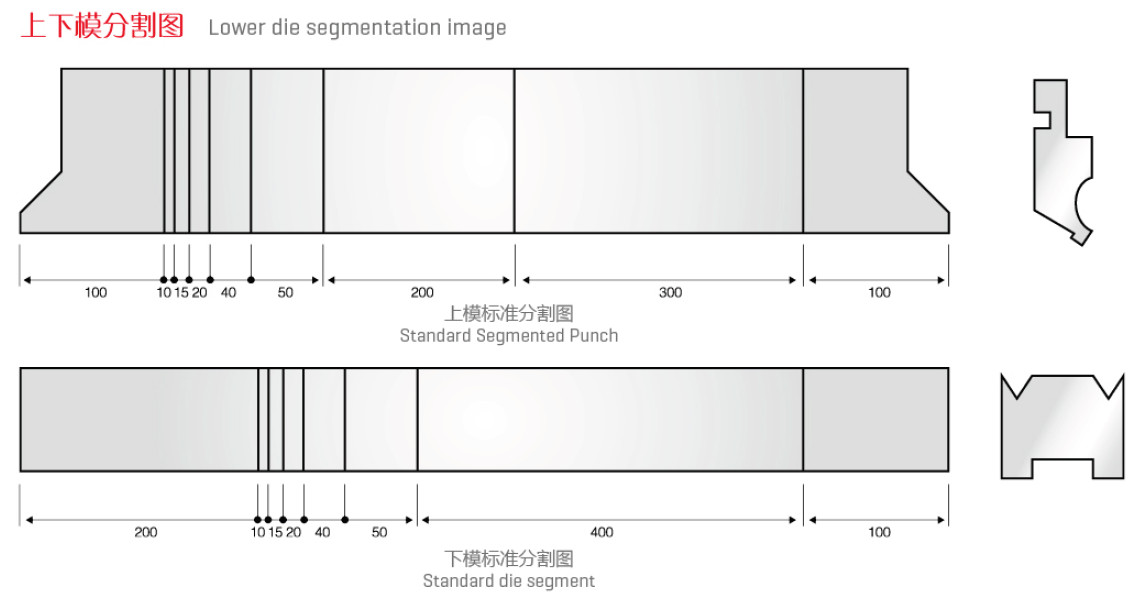

6. Feer qaybsan ayaa lagu dari karaa dherer gaar ah iyadoo loo eegayo shuruudaha foorarsiga ee qalabka shaqada ee gaarka ah.

7.Hydraulic punch auto clamping ama makaanik degdeg ah xajin kara waxaa lagu qalabayn karaa ikhtiyaarka ah si loo yareeyo culayska shaqada iyo hagaajinta hufnaanta shaqada.

8. Nidaamka CNC wuxuu qaataa nidaamka Delem CNC. Nidaamkan CNC waxaa lagu soo bandhigay wareeggii ugu dambeeyay ee elektiroonigga ah, midabka dhabta ah ee TFT oo leh saamiga xallinta sare iyo liiska luqadaha badan. Waa nidaamka xakamaynta heerka koowaad ee mashiinka foorarsiga caalamiga ah.

9. Qalabka magdhowga dhuunta nooca C waxaa lagu rakibay dhuunta qalabka mashiinka, kaas oo ku xiran qalabka lagu ogaanayo. Qallafsanaanta yar yar ee xoogga foorarsiga ma saameyn doonto saxnaanta cabbirka nidaamka, iyo saxnaanta leexinta dhumuc kasta iyo saxan kasta oo qalab ah ayaa la hubin karaa.

10, Taageeraha hore iyo hagaha safka ayaa dhaqdhaqaaqa ka dhigaya mid fudud

Delem DA66T nidaamka xakamaynta CNC oo leh heer caalami ah oo horumarsan

1. Nidaamka hawlgalka WINDOWS® oo buuxa, wuxuu ogaan karaa xiritaanka mashiinka degdegga ah;

2. Xulashada luqado badan oo leh hawlgal ku habboon;

3. Nashqada muuqaalka moodada leh oo leh hawlgal dadka ku jihaysan;

4. Qaab dhismeedka module garaadka, nidaamka waxaa lagu kordhin karaa 24 faas;

5. 17 "TFT muuqaalka LCD midabka dhabta ah, barnaamijka garaafyada 2D;

6. PLC-ga la dhisay si loo yareeyo naqshadeynta wareegga iyo kordhinta kalsoonida;

7. Deked jiirka USB, dekedda keyboard;

8. Isku-ururinta tooska ah ee wakhtiga shaqada iyo wakhtiyada foorarsiga;

9. Habka qalooca isku-dubbarid toos ah iyo jilitaanka foorarsiga;

10. Soo dhawoow bilaashka ah muuqaalka mishiinka, qalabka iyo qalabka shaqada ee heerka 1:1:1 oo leh qaab garaaf;

11.Digital, graphic iyo hababka kale ee barnaamijka dhinta, flat die, arc dhinta waaweyn, caaryada V jeexdin badan, variable V jeexdin caaryada;

+

13. Khaladka nidaamka digniinta si looga fogaado hawl-xumada;

14. Awoodda xusuusta 1G

15. Cilad fog;

16. Software falanqaynta khaaska ah ee mashiinka, kormeerka waqtiga-dhabta ah;

17. Barnaamijyada khaaska ah ee ka baxsan khadka ayaa yarayn kara wakhtiga barnaamijyada waxayna kordhin karaan waxtarka;

18. nidaamka maamulka faylka ku dhex jira, tifaftiraha qoraalka;

19. Hawlgalka Tandem;

20. Gudida hawlgalku waxa ay ku qalabaysan yihiin joogsi degdeg ah, slider dhaqaaqa gacanta iyo aragtida ergonomics.

Nidaamka T-3500TCNC

1 Isticmaal nidaamka hawlgalka WINDOWS ee waqtiga-dhabta ah, waxay ogaan kartaa xidhitaanka degdega ah;

2 nooc oo kala doorasho luqadeed ah, waxaa lagu dejin karaa interface-ka Ingiriisiga, fududahay in lagu shaqeeyo;

3 naqshadaynta moodada, fududahay in lagu shaqeeyo, waxay ka tarjumaysaa dadka ku jihaysan;

4 heerka afar dhidib, modules dheeraad ah, taageertaa ilaa lix dhidib;

5.10 "TFT shaashadda midabka dhabta ah, shaashadda LCD taabashada, taabasho badan, barnaamij garaafyo laba-cabbir ah, bandhig 3D;

6-ku-dhismay shaqada PLC, yaraynta naqshadaynta wareegga, kordhi kalsoonida;

7.USB mouse interface, keyboard interface;

8 saacadood oo shaqo oo toos ah iyo wakhtiyo foorarsi;

9, garaafyada dhijitaalka ah iyo 2D barnaamij taabasho buuxa ah, habka foorarsiga muuqaalka 3D, habka foorarsiga si toos ah isu-ururinta iyo jilitaanka foorarsiga;

10. Qaabka mishiinka, caaryada iyo qaybta shaqada ayaa si xor ah loo soo dhoweeyay 1:1:1 marka loo eego garaafyada.

11, dhijitaal ah, graphic iyo hababka kale ee barnaamijka dhinta, flat die, dhinta arc weyn oo wareeg ah, caaryada V multi V, caaryada jeexdin V variable;

12. Khaladka nidaamka digniinta si looga fogaado hawl-xumada;

13. Awoodda xusuusta 1G

14. Software falanqaynta khaaska ah ee mashiinka, kormeerka waqtiga-dhabta ah;

15. nidaamka maamulka faylalka gundhig, tifaftiraha qoraalka;

16. Hawlgalka Tandem;

17. Gudida hawlgalka waxay ku qalabaysan tahay joogsiga degdega ah, slider dhaqaaqa gacanta iyo aragtida ergonomics.

Biriinka CNC Press Brake Mashiinka foorarsiga ee biriiga;

Holland DELEM DA52 Nidaamka CNC

1 Isticmaal nidaamka hawlgalka WINDOWS ee waqtiga-dhabta ah, waxay ogaan kartaa xidhitaanka degdega ah

2. Xulashada luqado badan oo leh hawlgal ku habboon;

3. Nashqada muuqaalka moodada leh oo leh hawlgal dadka ku jihaysan;

4. Qaab-dhismeedka qaab-dhismeedka caqliga leh, nidaamku wuxuu u fidin karaa dhidibka 4 si dabacsanaan leh

5.7"TFT LCD bandhigay;

6. PLC-ga la dhisay si loo yareeyo naqshadeynta wareegga iyo kordhinta kalsoonida;

7. Dekadda mouse USB, dekedda keyboard, dekedda RS232, dekedda badbaadada PLC;

8. Isku-ururinta tooska ah ee wakhtiga shaqada iyo wakhtiyada foorarsiga;

9. Barnaamijyada dhijitaalka ah;

10. Barnaamij-samaynta qaab-dhismeedka dhijitaalka ah;

11. Xogta saxda ah ee xagal toosan;

12, nidaamka digniinta khaladka si looga hortago khalkhalka;

13, awoodda xusuusta waa 64M;

14, software falanqaynta gaarka ah, kormeerka-waqtiga dhabta ah;

15, Hawlgalka Tandem;

16, guddida hawlgalka waxay ku qalabaysan tahay joogsi degdeg ah.

Holland DELEM DA53 Nidaamka CNC

1 Isticmaal nidaamka qalliinka ee DELEM-LINUX, waxay ogaan kartaa xiritaanka degdegga ah

2. Xulashada luqado badan oo leh hawlgal ku habboon;

3. Nashqada muuqaalka moodada leh oo leh hawlgal dadka ku jihaysan;

4. Qaab-dhismeedka qaab-dhismeedka caqliga leh, nidaamku wuxuu u fidin karaa dhidibka 4 si dabacsanaan leh

5. 10"TFT LCD bandhigay;

6. PLC-ga la dhisay si loo yareeyo naqshadeynta wareegga iyo kordhinta kalsoonida;

7. Dekadda mouse USB, dekedda keyboard, dekedda RS232, dekedda badbaadada PLC;

8. Isku-ururinta tooska ah ee wakhtiga shaqada iyo wakhtiyada foorarsiga;

9. Barnaamijyada taabashada dhijitaalka ah;

10. Barnaamij-samaynta qaab-dhismeedka dhijitaalka ah;

11. Xogta saxda ah ee xagal toosan;

12, nidaamka digniinta khaladka si looga hortago khalkhalka;

13, awoodda xusuusta waa 64M;

14, software falanqaynta gaarka ah, kormeerka-waqtiga dhabta ah;

15. Nidaamka maaraynta faylalka ku-xidhan, tifaftiraha qoraalka

16, Hawlgalka Tandem;

17, guddida hawlgalka waxay ku qalabaysan tahay joogsi degdeg ah.

| Maya | Sharaxaada | Tirada | Odhaah |

| 1 | Faylasha Hawlaha | Hal go'an | |

| 2 | Inner Hex Socket Spanner | Hal go'an | |

| 3 | Qoriga Dufan | Mid maya. | |

| 4 | Dhisidda Bolt | Hal go'an | |

| 5 | Hagaajinta Bolt | Hal go'an | |

| 6 | Xakamaynta cagaha | Mid maya. | |

| 7 | Qalabka caadiga ah | Hal go'an |

1. Saliida Haydarooliga: VG46# oo la soo dejiyay Saliida Haydarooliga; iyo tirada saliidda loo baahan yahay waxay kuxirantahay qeexida mashiinka;

2. Awoodda: 380V,50HZ, isbedbeddelka danabka 10% --5%

3. Heerkulka deegaanka: 0°C - +40°C

4. Qoyaanka deegaanka: qoyaan qaraabo ah 20-80% RH(aan-buuxin)

5. Ka fogow isha gariirka xooggan iyo faragelinta korantada

6. Boodh yar, oo aan lahayn gaas waxyeello leh ama daxalaysa

7. Diyaari aasaaska sida waafaqsan sawirka aasaasiga ah

8. Dooro shaqaalaha qaraabada ah ee leh asal waxbarasho gaar ah oo loogu talagalay habaynta muddada fog sidii hawlwadeenka mashiinka.

| Maya | Sharaxaada | Tirada | Odhaah |

| 1 | Faylasha Hawlaha | Hal go'an | |

| 2 | Inner Hex Socket Spanner | Hal go'an | |

| 3 | Qoriga Dufan | Mid maya. | |

| 4 | Dhisidda Bolt | Hal go'an | |

| 5 | Hagaajinta Bolt | Hal go'an | |

| 6 | Xakamaynta cagaha | Mid maya. | |

| 7 | Qalabka caadiga ah | Hal go'an |

60T

| Tilmaamid | Unug | PR9 060/2550 | |

| Max. Xoog qalooca | KN | 600 | |

| Max. Dhererka foorarsiga | mm | 2550 | |

| Fogaanta tiirka | mm | 2150 | |

| Qoto dheer ee cunaha | mm | 350 | |

| Ram Stroke | mm | 215 | |

| Dhererka xiran | mm | 530 | |

| Xawaaraha ku dhow | mm/s | 200 | |

| Xawaaraha shaqada | mm/s | 18 | |

| Xawaaraha soo celinta | mm/s | 200 | |

| Awoodda Matoorka ugu weyn | Kw | 7.5 | |

| Nidaamka CNC | Holland Delem DA66T ama DA52S ama DA53T ama T-3500T CNC nidaamka xakameynaya Y1, Y2, X, R, Z1, Z2 faashash iyo taaj farsamo. | ||

| Awoodda Haamaha Shidaalka | L | 300 | |

| X dhidibka | Saxnaanta | mm | ±0.1 |

| Faalig | mm | 500 | |

| Xawaaraha | mm/s | 400 | |

| Awood | Kw | 0.85 | |

| R dhidibka | Saxnaanta | mm | ±0.1 |

| Faalig | mm | 200 | |

| Xawaaraha | mm/s | 200 | |

| Awood | Kw | 0.85 | |

| Z1,Z2 dhidibka | Saxnaanta | mm | ±0.1 |

| Faalig | mm | 1250 | |

| Xawaaraha | mm/s | 1200 | |

| Awood | Kw | 0.75 | |

| Qiyaasta dulucda | Dhererka | mm | 3400 |

| Ballaca | mm | 1400 | |

| Dhererka | mm | 2510 | |

100T

| Tilmaamid | Unug | PR9 100/3100 | PR9 100/4100 | |

| Max. Xoog qalooca | KN | 1000 | 1000 | |

| Max. Dhererka foorarsiga | mm | 3100 | 4100 | |

| Fogaanta tiirka | mm | 2700 | 3700 | |

| Qoto dheer ee cunaha | mm | 420 | 420 | |

| Ram Stroke | mm | 265 | 265 | |

| Dhererka xiran | mm | 530 | 530 | |

| Xawaaraha ku dhow | mm/s | 220 | 220 | |

| Xawaaraha shaqada | mm/s | 17 | 13 | |

| Xawaaraha soo celinta | mm/s | 220 | 150 | |

| Awoodda Matoorka ugu weyn | Kw | 15 | 11 | |

| Nidaamka CNC | Holland Delem DA66T ama DA52S ama DA53T ama T-3500T CNC nidaamka xakameynaya Y1, Y2, X, R, Z1, Z2 faashash iyo taaj farsamo. | |||

| Awoodda Haamaha Shidaalka | L | 350 | 500 | |

| X dhidibka | Saxnaanta | mm | ±0.1 | ±0.1 |

| Faalig | mm | 500 | 500 | |

| Xawaaraha | mm/s | 400 | 400 | |

| Awood | Kw | 0.85 | 0.85 | |

| R dhidibka | Saxnaanta | mm | ±0.1 | ±0.1 |

| Faalig | mm | 200 | 200 | |

| Xawaaraha | mm/s | 200 | 200 | |

| Awood | Kw | 0.85 | 0.85 | |

| Z1,Z2 dhidibka | Saxnaanta | mm | ±0.1 | ±0.1 |

| Faalig | mm | 1850kii | 2800 | |

| Xawaaraha | mm/s | 1200 | 1200 | |

| Awood | Kw | 0.75 | 0.75 | |

| Qiyaasta dulucda | Dhererka | mm | 3450 | 4450 |

| Ballaca | mm | 1600 | 1600 | |

| Dhererka | mm | 2750 | 2710 | |

150T

| Tilmaamid | Unug | PR9 150/3100 | PR9 150/4100 | |

| Max. Xoog qalooca | KN | 1500 | 1500 | |

| Max. Dhererka foorarsiga | mm | 3100 | 4100 | |

| Fogaanta tiirka | mm | 2700 | 3700 | |

| Qoto dheer ee cunaha | mm | 420 | 420 | |

| Ram Stroke | mm | 265 | 265 | |

| Dhererka xiran | mm | 530 | 530 | |

| Xawaaraha ku dhow | mm/s | 180 | 180 | |

| Xawaaraha shaqada | mm/s | 11 | 11 | |

| Xawaaraha soo celinta | mm/s | 150 | 150 | |

| Awoodda Matoorka ugu weyn | Kw | 15 | 15 | |

| Nidaamka CNC | Holland Delem DA66T ama DA52S ama DA53T ama T-3500T CNC nidaamka xakameynaya X, Y1, Y2, R, Z1, Z2 faashash iyo taaj farsamo. | |||

| Awoodda Haamaha Shidaalka | L | 440 | 600 | |

| Tirada Haamaha Shidaalka | maya | 3 | 4 | |

| X dhidibka | Saxnaanta | mm | ±0.10 | ±0.1 |

| Faalig | mm | 500 | 500 | |

| Xawaaraha | mm | 500 | 400 | |

| Awood | kw | 0.85 | 0.85 | |

| R dhidibka | Saxnaanta | mm | ±0.10 | ±0.1 |

| Faalig | mm | 200 | 200 | |

| Xawaaraha | mm | 200 | 200 | |

| Awood | kw | 0.85 | 0.85 | |

| Z1,Z2 dhidibka | Saxnaanta | mm | ±0.10 | ±0.1 |

| Xawaaraha | mm | 1200 | 1200 | |

| Faalig | mm | 1850kii | 2800 | |

| Awood | kw | 0.75 | 0.75 | |

| Qiyaasta dulucda | Dhererka | mm | 3470 | 4470 |

| Ballaca | mm | 1720kii | 1720kii | |

| Dhererka | mm | 2700 | 2710 | |

PR9 060

| Maya | Magaca | Qaabka | Summada | |

| 1 | Nidaamka CNC | DA66T/T-3500T/DA52S ama DA53T CNC System | Holland DELEM | |

| 2 | Servo Motor | ECMA-E21315RS/SGM7G-09AFC61 | DELTA AMA YASAKAWA | |

| 3 | Servo Driver | ASD-B2-1521-B/SGD7S-7R6A00A002 | DELTA AMA YASAKAWA | |

| 4 | Nidaamka Haydarooliga | Habka Electro-hydraulic | Jarmalka Bosch-Rexroth ama Germany HOERBIGER | |

| Isku-xidhka xakamaynta isku-dhafka | a. valve cadaadiska | |||

| b. waalka firfircoon | ||||

| c. Qulqulka servo valve iwm. | ||||

| Xakamaynta Haydarooliga | a. waalka kartoonada | |||

| b. valve cadaadiska saamiga | ||||

| c. valve dooriye | ||||

| d. valve decompress saamiga | ||||

| e. valve cadaadiska iwm. | ||||

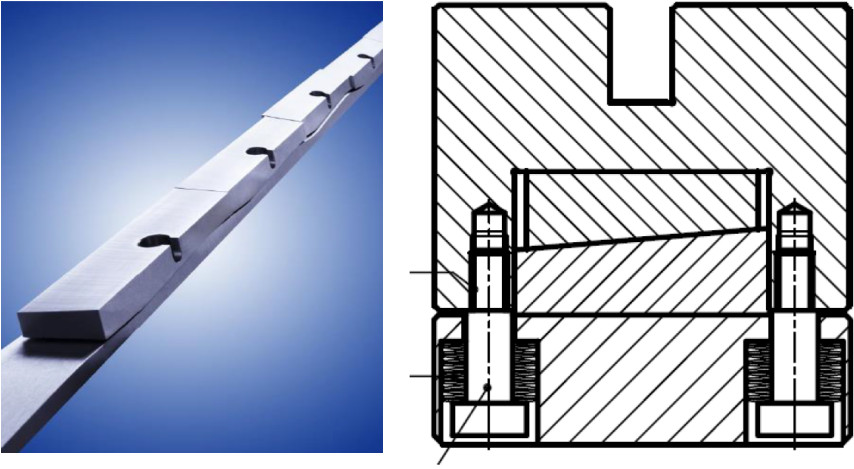

| 5 | Jidka toosan | 35A---760L AMA 35E-760L | THK AMA PMI | |

| 6 | Ballscrew | 25/20-1000L ama R25/20-880/1000 | THK AMA PMI | |

| 7 | Bamka saliidda | PGH3-2X/016RE071VU2 | Jarmalka Rexroth | |

| 8 | Xidhmada xidhidhiyaha dhamaystiran ee dhululubada saliidda | USA PARKER | USA PARKER | |

| 9 | Xidhmada dhuumaha cadaadiska sare oo dhamaystiran | 1.GE16 ZSR 3/4EDCF | USA PARKER, EO-2 tuubooyinka wadajirka ah ama Germany VOSS wadajirka tuubooyinka | |

| 2.GE28 LR3/4EDOMDCF | ||||

| 3.W10 ZLCF | ||||

| 4.TH10 ZLR KDSCF | ||||

| 5.WH10 ZSR KDSCF iwm. | ||||

| 10 | Isku-xidhka | R38 25/42 | Jarmalka KTR | |

| 11 | Xiriiriyaha AC | LC1-D1810B7, LC1-D0910B7N iwm. | Schneider | |

| 12 | Bedelka u dhowaanshaha | TP-SM5P2 iwm. | KU DHAQAN | |

| 13 | hogaanka Terminalka | UK2.5B, UK10N iwm. | Phoenix | |

| 14 | Badhanka | XB2-BVB3LC iwm. | Schneider | |

| 15 | Rinjiyeynta | Holland SIKKENS | ||

| 16 | Taaj | Summada qaranka (heerka) | SREE/MIDOWGA | |

| 17 | Taaj | La soo dejiyay (ikhtiraac) | VILLA | |

| 18 | Taageere hore | heerka | JFY | |

PR9 100

| Maya | Magaca | Qaabka | Summada | |

| 1 | Nidaamka CNC | DA66T ama DA52S ama DA53T ama T-3500T CNC System | Holland DELEM | |

| 2 | Servo Motor | ECMA-E21315RS/SGM7G-09AFC61 | DELTA AMA YASAKAWA | |

| 3 | Servo Driver | ASD-B2-1521-B/SGD7S-7R6A00A002 | DELTA AMA YASAKAWA | |

| 4 | Nidaamka Haydarooliga | Habka Electro-hydraulic | Jarmalka Bosch-Rexroth ama Germany HOERBIGER | |

| Isku-xidhka xakamaynta isku-dhafka | a. valve cadaadiska | |||

| b. waalka firfircoon | ||||

| c. Qulqulka servo valve iwm. | ||||

| Xakamaynta Haydarooliga | a. waalka kartoonada | |||

| b. valve cadaadiska saamiga | ||||

| c. valve dooriye | ||||

| d. valve decompress saamiga | ||||

| e. valve cadaadiska iwm. | ||||

| 5 | Jidka toosan | 35A-760L AMA 35E-760L | THK AMA PMI | |

| 6 | Ballscrew | 20/25-880/1000 AMA R25/20-880/1000 | THK AMA PMI | |

| 7 | Bamka saliidda | PGH4-3X/032RE071VU2 | Jarmalka Rexroth | |

| IPVAP5-32 | Germany VOITH | |||

| HQI3-32 | Jarmalka Eckerle | |||

| 8 | Xidhmada xidhidhiyaha dhamaystiran ee dhululubada saliidda | USA PARKER | USA PARKER | |

| 9 | Xidhmada dhuumaha cadaadiska sare oo dhamaystiran | 1.GE16 ZSR 3/4EDCF | USA PARKER, EO-2 tuubooyinka wadajirka ah ama Germany VOSS wadajirka tuubooyinka | |

| 2.GE28 LR3/4EDOMDCF | ||||

| 3.W10 ZLCF | ||||

| 4.TH10 ZLR KDSCF | ||||

| 5.WH10 ZSR KDSCF iwm. | ||||

| 10 | Isku-xidhka | R38 25/42 | Jarmalka KTR | |

| 11 | Xiriiriyaha AC | LC1-D1810B7, LC1-D0910B7N iwm. | Schneider | |

| 12 | Bedelka u dhowaanshaha | TP-SM5P2 iwm. | KU DHAQAN | |

| 13 | hogaanka Terminalka | UK2.5B, UK10N iwm. | Phoenix | |

| 14 | Badhanka | XB2-BVB3LC iwm. | Schneider | |

| 15 | Rinjiyeynta | KAILEDI | ||

| 16 | Taaj | Summada qaranka (heerka) | SREE/MIDOWGA | |

| 17 | Taaj | La soo dejiyay (ikhtiraac) | VILLA | |

| 18 | Taageere hore | heerka | JFY | |

PR9 150

| Maya | Magaca | Qaabka | Summada | |

| 1 | Nidaamka CNC | DA66T ama DA52S ama DA53T ama T-3500T CNC System | Holland DELEM | |

| 2 | Servo Motor | ECMA-E21315RS/SGM7G-09AFC61 | DELTA AMA YASAKAWA | |

| 3 | Servo Driver | ASD-B2-1521-B/SGD7S-7R6A00A002 | DELTA AMA YASAKAWA | |

| 4 | Nidaamka Haydarooliga | Habka Electro-hydraulic | Jarmalka Bosch-Rexroth | |

| Isku-xidhka xakamaynta isku-dhafka | a. valve cadaadiska | |||

| b. waalka firfircoon | ||||

| c. Qulqulka servo valve iwm. | ||||

| Xakamaynta Haydarooliga | a. waalka kartoonada | |||

| b. valve cadaadiska saamiga | ||||

| c. valve dooriye | ||||

| d. valve decompress saamiga | ||||

| e. valve cadaadiska iwm. | ||||

| 5 | Jidka toosan | 35A-760L AMA 35E-760L | THK AMA PMI | |

| 6 | Ballscrew | 20/25-880/1000 AMA R25/20-880/1000 | THK AMA PMI | |

| 7 | Bamka saliidda | PGH4-3X/032RE071VU2 | Jarmalka Rexroth | |

| IPVAP5-32 | Germany VOITH | |||

| HQI3-32 | Jarmalka Eckerle | |||

| 8 | Xidhmada xidhidhiyaha dhamaystiran ee dhululubada saliidda | USA PARKER | USA PARKER | |

| 9 | Xidhmada dhuumaha cadaadiska sare oo dhamaystiran | 1.GE16 ZSR 3/4EDCF | USA PARKER, EO-2 tuubooyinka wadajirka ah ama Germany VOSS wadajirka tuubooyinka | |

| 2.GE28 LR3/4EDOMDCF | ||||

| 3.W10 ZLCF | ||||

| 4.TH10 ZLR KDSCF | ||||

| 5.WH10 ZSR KDSCF iwm. | ||||

| 10 | Isku-xidhka | R38 25/42 | Jarmalka KTR | |

| 11 | Xiriiriyaha AC | LC1-D1810B7, LC1-D0910B7N iwm. | Schneider | |

| 12 | Bedelka u dhowaanshaha | TP-SM5P2 iwm. | KU DHAQAN | |

| 13 | hogaanka Terminalka | UK2.5B, UK10N iwm. | Phoenix | |

| 14 | Badhanka | XB2-BVB3LC iwm. | Schneider | |

| 15 | Rinjiyeynta | KAILEDI | ||

| 16 | Taaj | Summada qaranka (heerka) | SREE/MIDOWGA | |

| 17 | Taaj | La soo dejiyay (ikhtiraac) | VILLA | |

| 18 | Taageere hore | heerka | JFY | |

Biriinka CNC Press Brake Mashiinka foorarsiga ee biriiga;