Mashiinka Shearing CNC Tayada Sare

1. Qalabka mashiinka oo dhan waxaa farsameeyay Jarmalka SHW pentahedron xarunta hal mar.

4. xagasha xiirashada si fudud ayaa loo hagaajin karaa iyada oo loo marayo barnaamijka si looga fogaado qallafsanaanta qalabka shaqada ee ay keento goynta.

5. Dhererka istaroogga bim ee sare si toos ah ayaa loo hagaajin karaa si loo ogaado goynta degdega ah ee saxda ah ee gaaban iyo yar yar si loo hagaajiyo waxtarka shaqada.

6. Nidaamka CNC wuxuu si toos ah u hagaajin doonaa farqiga daabadaha iyadoo loo eegayo dhumucda xaashida kala duwan iyo walxaha si loo hagaajiyo tayada goynta.

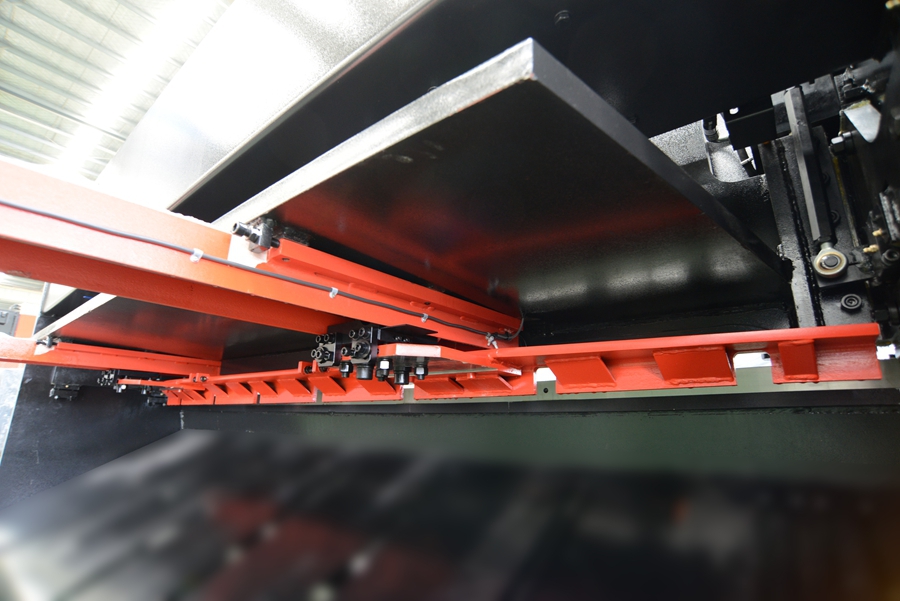

7. daab afar geesood ah ayaa la qaatay si loo wanaajiyo nolosha adeega daabka taasoo aad uga wanaagsan kan lulida.

8. Naqshad cusub oo dhabarka ah, qaab dhismeedka xasilloon, hagaajinta iska caabbinta Wear, khasaare badan

2. Wuxuu qaataa nidaamka Delem DAC360 CNC:

● si sax ah u xakamee qiyaasta dambe

●si sax ah u xakameey faaliga xiirida

● si sax ah u xakamee xagasha xiirashada

●si sax ah u kontorool nadiifinta biraha

●si sax ah u xakameey tirada shaqooyinka.

3. Wuxuu qaataa Jarmalka BOSCH habka biyo-dharka isku dhafan:

● si loo fududeeyo dhuumaha

●si looga fogaado daadinta saliidda

● si loo hagaajiyo xasiloonida shaqada

● si loo qurxiyo muuqaalka mashiinka

1. loo isticmaalo xakamaynta auto ee mishiinka dhogorta leh oo si buuxda u shaqaynaysa quudinta hore ama dhabarka

2. wuxuu qaataa muuqaal LCD ah oo qeexan, barnaamijka nooca menu;

3. xagasha xiirashada, farqiga daab, xiirid istaroogga auto xisaabinta iyo xakamaynta;

4. Dhisme qaabaysan, qeexid dabacsan ama fidin X1-X2 xakamaynta quudinta isku xidhan iyo xakamaynta dhidibka Z;

5. qaataa boos buuxa iyo barnaamij meelayn qaraabo ah;

6. Raadinta auto ee barta tixraaca, iyo booska xusuusta ayaa la dejin karaa;

7. naqshadeynta giraangiraha gacanta ee gaarka ah si loo sameeyo hagaajinta mashiinka si habboon;

8. RS232 interface interface;

9. soo saarista calaamado caawiye ah oo lagu qeexay isticmaale badan;

10. barnaamijka is-ogaanshaha;

11. kaydinta gudaha ee 100 khadka barnaamijka;

12. 4.7 inch LCD qeexitaan sare;

13. shaqada tirinta barnaamijka;

14. xulashada halbeegga cabbirka ee u dhexeeya nidaamka metric iyo nidaamka Ingiriisiga.

| Maya | Shayga | Qty. | Odhaah |

| 1 | Files Machine | Hal go'an | |

| 2 | Hex Socket Spanner | Hal go'an | |

| 3 | Qoriga Dufan | Mid maya. | |

| 4 | Dhisidda Bolt | Hal go'an | |

| 5 | Hagaajinta Bolt | Hal go'an | |

| 6 | Xakamaynta cagaha | Mid maya. |

1. Ilaha hawada: hubi in cadaadiska gaaska ee mishiinku uu ka badan yahay 0.6 Mpa, socodka gaaska waa inuu ka badan yahay 0.3 m3 / min.

2. Saliida Haydarooliga: Saliida hydraulic ee VG46# oo dibada laga keenay. Tirada saliidda ee loo baahan yahay waa hoos:

| Qaabka Mashiinka | Tirada Saliida (L) |

| Taxanaha VR6,VR8 | 230 |

| Taxanaha VRZ | 690 |

| Taxanaha VR10 | 370 |

| VR13*3200 | 460 |

| VR13*6200 | 800 |

3.Power: 380V,50HZ, korantada isbedbeddelka ± 10%

4. Heerkulka deegaanka: 0°C - +40°C

5. Qoyaanka deegaanka: qoyaan qaraabo ah 20-80% RH(aan-buuxin)

6. Ka fogow isha gariirka xooggan iyo faragelinta korantada

7. Boodh yar, oo aan lahayn gaas waxyeello leh ama daxalaysa

8. Diyaari aasaaska sida waafaqsan sawirka aasaasiga ah

9. U dooro shaqaalaha qaraabada ah ee leh asal waxbarasho gaar ah oo loogu talagalay habayn muddo dheer ah sidii shaqaaleeye mashiinka.

Mashiinka Shearing CNC; xiiritaanka guillotine Haydarooliga; Mashiinka dhogorta;

2500

| Sharaxaada | Unug | 6*2500 | |

| Dhumucda xiiridda (mm) | Bir khafiif ah 450Mpa | mm | 0.5-6 |

| Birta Aan Lahayn 600Mpa | 0.5-4 | ||

| Aluminium 300Mpa | 0.5-8 | ||

| Dhererka Xiritaanka | mm | 2500 | |

| Xagasha Xiritaanka | ° | 0.5°~2° | |

| Dib-u- qiyaas | Faalig mm | mm | 5 ~ 1000 |

| Xawaaraha mm/s | mm/s | ≤250 | |

| Saxnimada mm | mm | ±0.1 | |

| Servo Motor Power KW | KW | 1 | |

| Waqtiyada istaroogga | hpm | 25-36 | |

| Awoodda Baaloodh (L) | L | 230 | |

| Tirada isku-qabsiga | maya | 12 | |

| Awoodda Baabuurka ugu Weyn (KW) | KW | 11 | |

| Nidaamka CNC | Holland Delem DAC360 Nidaamka CNC ee xakameynaya xagasha xiirashada, farqiga daabadaha, iyo istaroogga xiirashada | ||

| Tirada iyo dhererka cududda taageerada (mm) | mm | 3*1400 | |

| Qiyaasta dulucda | Dhererka (mm) | mm | 3110 |

| Ballaca (mm) | mm | 3000 | |

| Dhererka (mm) | mm | 1705 | |

3000/3200

| Sharaxaada | Unug | 6*3000 | 8*3000 | 10*3000 | 13*3200 | 16*3200 | ||||

| Dhumucda xiiridda (mm) | Bir khafiif ah 450Mpa | mm | 0.5-6 | 0.8-8 | 0.8-10 | 1-13 | 1-16 | |||

| Birta Aan Lahayn 600Mpa | 0.5-4 | 0.8-5 | 0.8-7 | 1-8 | 1-10 | |||||

| Aluminium 300Mpa | 0.5-8 | 0.8-10 | 0.8-12 | 1-18 | 1-20 | |||||

| Dhererka Xiritaanka | mm | 3070 | 3070 | 3070 | 3200 | 3200 | ||||

| Xagasha Xiritaanka | ° | 0.5°-2° | 0.5°-2° | 0.5°-2° | 0.5°-2° | 0.5°-2° | ||||

| Dib-u- qiyaas | Faalig mm | mm | 5 ~ 1000 | 5 ~ 1000 | 5 ~ 1000 | 5-1000 | 5-1000 | |||

| Xawaaraha mm/s | mm/s | ≤250 | ≤250 | ≤250 | 200 | 200 | ||||

| Saxnimada mm | mm | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ||||

| Servo Motor Power KW | KW | 1 | 1 | 1 | 1.0 | 1.0 | ||||

| Waqtiyada istaroogga | hpm | 22-35 | 16-34 | 15-32 | 10-15 | 9-16 | ||||

| Awoodda Baaloodh (L) | L | 230 | 230 | 370 | 460 | 460 | ||||

| Tirada isku-qabsiga | maya | 14 | 14 | 14 | 15 | 15 | ||||

| Awoodda Baabuurka ugu Weyn (KW) | KW | 11 | 15 | 22 | 30 | 37 | ||||

| Nidaamka CNC | Holland Delem DAC360 Nidaamka CNC ee xakameynaya xagasha xiirashada, farqiga daabadaha, iyo istaroogga xiirashada | |||||||||

| Tirada iyo dhererka cududda taageerada (mm) | mm | 3*1400 | 3*1400 | 3*1400 | 3*1000 | 3*1000 | ||||

| Qiyaasta dulucda | Dhererka (mm) | mm | 3610 | 3640 | 3720 | 4075 | 4300 | |||

| Ballaca (mm) | mm | 3000 | 3000 | 3040 | 2752 | 3000 | ||||

| Dhererka (mm) | mm | 1705 | 1755kii | 1880kii | 2432 | 2850 | ||||

4000

| Sharaxaada | Unug | 6*4000 | 8*4000 | 10*4000 | 13*4000 | 16*4000 | ||||||

| Dhumucda xiiridda (mm) | Bir khafiif ah 450Mpa | mm | 0.5-6 | 0.8-8 | 0.8-10 | 1-13 | 1-16 | |||||

| Birta Aan Lahayn 600Mpa | 0.5-4 | 0.8-5 | 0.8-7 | 1-8 | 1-10 | |||||||

| Aluminium 300Mpa | 0.5-8 | 0.8-10 | 0.8-12 | 1-18 | 1-20 | |||||||

| Dhererka Xiritaanka | mm | 4070 | 4070 | 4070 | 4000 | 4000 | ||||||

| Xagasha Xiritaanka | ° | 0.5°~2° | 0.5°~2° | 0.5°~2° | 0.5°~2.5° | 0.5°~2.5° | ||||||

| Dib-u- qiyaas | Faalig mm | mm | 5 ~ 1000 | 5 ~ 1000 | 5 ~ 1000 | 5-1000 | 5-1000 | |||||

| Xawaaraha mm/s | mm/s | ≤250 | ≤250 | ≤250 | ≤200 | ≤200 | ||||||

| Saxnimada mm | mm | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ||||||

| Servo Motor Power KW | KW | 1 | 1 | 1 | 1.0 | 1.0 | ||||||

| Waqtiyada istaroogga | hpm | 16 ~ 34 | 14 ~ 32 | 12 ~ 32 | 10-15 | 8-15 | ||||||

| Awoodda Baaloodh (L) | L | 230 | 230 | 370 | 460 | 460 | ||||||

| Tirada isku-qabsiga | maya | 18 | 18 | 18 | 19 | 19 | ||||||

| Awoodda Baabuurka ugu Weyn (KW) | KW | 11 | 15 | 22 | 30 | 37 | ||||||

| Nidaamka CNC | Holland Delem DAC360 Nidaamka CNC ee xakameynaya xagasha xiirashada, farqiga daabadaha, iyo istaroogga xiirashada | |||||||||||

| Tirada iyo dhererka cududda taageerada (mm) | mm | 4*1400 | 4*1400 | 4*1400 | 4*1000 | 4*1000 | ||||||

| Qiyaasta dulucda | Dhererka (mm) | mm | 4610 | 4640 | 4720 | 4970 | 5300 | |||||

| Ballaca (mm) | mm | 3000 | 3000 | 3040 | 2760 | 3000 | ||||||

| Dhererka (mm) | mm | 1705 | 1705 | 1880kii | 2562 | 2850 | ||||||

6000/6200

| Sharaxaada | Unug | 6*6000 | 8*6000 | 13*6200 | 16*6000 | 16*6200 | |||

| Dhumucda xiiridda (mm) | Bir khafiif ah 450Mpa | mm | 0.5 ~ 6 | 0.8 ~ 8 | 1-13 | 1-16 | 1-16 | ||

| Birta Aan Lahayn 600Mpa | 0.5 ~ 4 | 0.8 ~ 5 | 1-8 | 1-10 | 1-10 | ||||

| Aluminium 300Mpa | 0.5 ~ 8 | 0.8-10 | 1-18 | 1-20 | 1-20 | ||||

| Dhererka Xiritaanka | mm | 6140 | 6140 | 6200 | 6000 | 6200 | |||

| Xagasha Xiritaanka | ° | 0.5˚-2˚ | 0.5˚-2.5˚ | 0.5˚-2.5˚ | 0.5˚-2.5˚ | 0.5˚-2˚ | |||

| Dib-u- qiyaas | Faalig mm | mm | 5-1000 | 5-1000 | 5-1000 | 5-1000 | 5-1000 | ||

| Xawaaraha mm/s | mm/s | 200 | 200 | 200 | 200 | 200 | |||

| Saxnimada mm | mm | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | |||

| Servo Motor Power KW | KW | 1.0 | 1.0 | 1.0 | 1.5 | 2.0 | |||

| Waqtiyada istaroogga | hpm | 12 ~ 20 | 12 ~ 20 | 6-10 | 5-9 | 5-9 | |||

| Awoodda Baaloodh (L) | L | 690 | 690 | 800 | 800 | 800 | |||

| Tirada isku-qabsiga | maya | 29 | 29 | 27 | 27 | 27 | |||

| Awoodda Baabuurka ugu Weyn (KW) | KW | 11 | 15 | 30 | 37 | 37 | |||

| Nidaamka CNC | Holland Delem DAC360 Nidaamka CNC ee xakameynaya xagasha xiirashada, farqiga daabadaha, iyo istaroogga xiirashada | ||||||||

| Tirada iyo dhererka cududda taageerada (mm) | mm | 6*1000 | 6*1000 | 6*1000 | 6*1000 | 6*1000 | |||

| Qiyaasta dulucda | Dhererka (mm) | mm | 7055 | 7115 | 7220 | 7300 | 7500 | ||

| Ballaca (mm) | mm | 2686 | 2690 | 2945 | 3000 | 3000 | |||

| Dhererka (mm) | mm | 2495 | 2680 | 2850 | 2850 | 2850 | |||

VR (Z) Taxane:

| Maya | Magaca | Qaabka | Summada |

| 1 | Nidaamka CNC | DAC360 Nidaamka CNC | Holland Delem |

| 2 | Servo Motor | EMJ-10APB22 | Estun |

| 3 | Servo Driver | RONET-E-10A-AMA | Estun |

| 4 | Nidaamka Haydarooliga | Qalabka korantada ee korantada-servo | Jarmalka Bosch-Rexroth |

| a.Valka cadaadiska saamiga | |||

| b. kartridge valve | |||

| c | |||

| d.labada cadaadiska | |||

| e. kontoroolka haydarooliga ee hal-jidka ah | |||

| f. waalka ceejinta | |||

| e.hal-jidka waalka iwm. | |||

| 5 | Jidka toosan | HSR25A-1240L | THK ama PMI |

| 6 | Ballscrew | 25/20-1400mm | THK ama PMI |

| 7 | Bamka saliidda | IPH-5B-50-11 ama PGH4-3X/050-E11VU2 | Japan NACHI bamka ama Germany Rexroth |

| 8 | Xidhmada xidhidhiyaha dhamaystiran ee dhululubada saliidda | USA PARKER | USA PARKER |

| 9 | Xidhmada dhuumaha cadaadiska sare oo dhamaystiran | 1.F372C91C161608-1200mm | USA PARKER, EO-2 tuubooyinka wadajirka ah ama Germany VOSS wadajirka tuubooyinka |

| 2.F372C91C161608-1950mm (2950mm) | |||

| 3.F381CACF151508-1480mm | |||

| 4.F381CFCF151508-2140mm (3140mm) | |||

| 5.F451TCCACF121206-1600mm | |||

| 6.F3720C19201612-1300mm Ama F3720C1C202512-1300mm | |||

| 7.GE12ZLREDC | |||

| 8.GE16SREDOMDCF | |||

| 9.GE42ZLREDCF iwm. | |||

| 10 | Isku-xidhka | R38 25.385/42 iwm. | Jarmalka KTR |

| 11 | Xiriiriyaha AC | LC1-D38B7C, LC1-D25B7Ciwm. | Schneider |

| 12 | Bedelka u dhowaanshaha | TP-SM5P2 iwm. | KU DHAQAN |

| 13 | hogaanka Terminalka | TB2.5B TB16ICH iwm. | Phoenix |

| 14 | Badhanka | XB2-BVB3LC iwm. | Schneider |

| 15 | Rinjiyeynta | KAILEDI |

VR (Z) Taxane:

| Maya | Magaca | Qaabka | Summada |

| 1 | Nidaamka CNC | DAC360 Nidaamka CNC | Holland Delem |

| 2 | Servo Motor | EMJ-10APB22 | Estun |

| 3 | Servo Driver | RONET-E-10A-AMA | Estun |

| 4 | Nidaamka Haydarooliga | Qalabka korantada ee korantada-servo | Jarmalka Bosch-Rexroth |

| a.Valka cadaadiska saamiga | |||

| b. kartridge valve | |||

| c | |||

| d.labada cadaadiska | |||

| e. kontoroolka haydarooliga ee hal-jidka ah | |||

| f. waalka ceejinta | |||

| e.hal-jidka waalka iwm. | |||

| 5 | Jidka toosan | HSR25A-1240L | THK ama PMI |

| 6 | Ballscrew | 25/20-1400mm | THK ama PMI |

| 7 | Bamka saliidda | IPH-5B-50-11 ama PGH4-3X/050-E11VU2 | Japan NACHI bamka ama Germany Rexroth |

| 8 | Xidhmada xidhidhiyaha dhamaystiran ee dhululubada saliidda | USA PARKER | USA PARKER |

| 9 | Xidhmada dhuumaha cadaadiska sare oo dhamaystiran | 1.F372C91C161608-1200mm | USA PARKER, EO-2 tuubooyinka wadajirka ah ama Germany VOSS wadajirka tuubooyinka |

| 2.F372C91C161608-1950mm (2950mm) | |||

| 3.F381CACF151508-1480mm | |||

| 4.F381CFCF151508-2140mm (3140mm) | |||

| 5.F451TCCACF121206-1600mm | |||

| 6.F3720C19201612-1300mm Ama F3720C1C202512-1300mm | |||

| 7.GE12ZLREDC | |||

| 8.GE16SREDOMDCF | |||

| 9.GE42ZLREDCF iwm. | |||

| 10 | Isku-xidhka | R38 25.385/42 iwm. | Jarmalka KTR |

| 11 | Xiriiriyaha AC | LC1-D38B7C, LC1-D25B7Ciwm. | Schneider |

| 12 | Bedelka u dhowaanshaha | TP-SM5P2 iwm. | KU DHAQAN |

| 13 | hogaanka Terminalka | TB2.5B TB16ICH iwm. | Phoenix |

| 14 | Badhanka | XB2-BVB3LC iwm. | Schneider |

| 15 | Rinjiyeynta | KAILEDI |