Mashiinka Punch CNC Turret Tayada Sare

1. Nidaamka hal-abuurka ah ee hal-abuurka ah, wuxuu qaataa qulqulka weyn ee servo motor-ka tooska ah iyo unugga wadista oo leh awood xad-dhaaf ah si loo xaqiijiyo isticmaalka tamarta hooseeya, waxtarka gudbinta sare, waxqabad la isku halleyn karo iyo dayactir ku habboon.

(1) Xawaaraha la hagaajin karo iyo istaroogga

a. Faaliga feerka waxaa loo dooran karaa iyadoo loo eegayo dhumucda xaashida si toos ah, taasoo hagaajinaysa hufnaanta shaqada.

b. Xawaaraha feerka waa la hagaajin karaa inta lagu guda jiro dhibic kasta oo xarun kasta,

c. Mashiinku wuxuu ogaan karaa xawaaraha sare ee xawaaraha sare inta lagu jiro orodka maran iyo xawaaraha hooseeya inta lagu jiro feerka dhabta ah, habkan, tayada feerka ayaa loo wanaajin karaa si wax ku ool ah, runtiina ma jiro wax buuq ah inta lagu jiro feerka.

(2). Nidaamku waxa uu leeyahay ilaalin xad dhaaf ah iyo qalabka ilaalinta culayska xad dhaafka ah.

(3). Xoogga feerka si toos ah ayaa loo hagaajin karaa iyadoo loo eegayo dhumucda xaashida iyo xawaaraha ordaya ee ram si tayada feerida ay u gaarto heer sare.

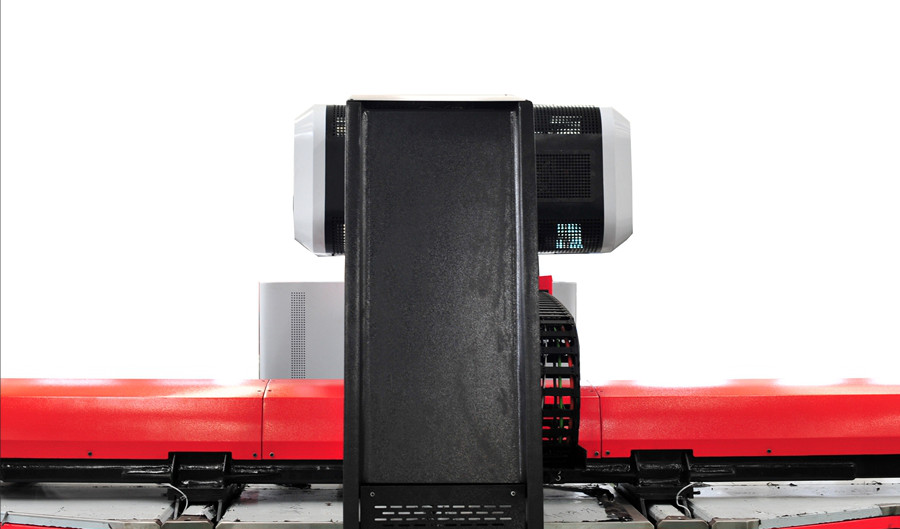

2. Turret leh baadiyaha waxa loo habeeyaa laba-labo

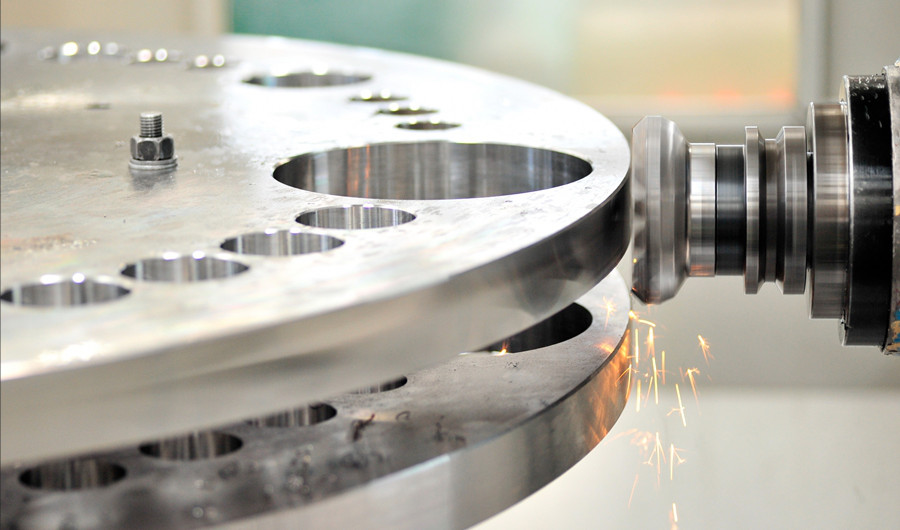

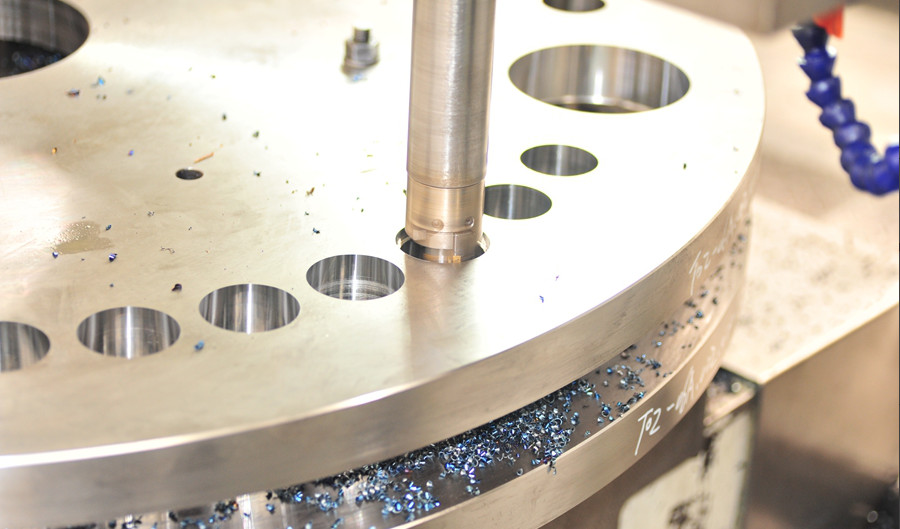

Turret waxaa lagu farsameeyaa qalab gaar ah si loo hubiyo coaxial ee turret sare iyo hoose iyo ballaariyo nolosha adeegga qalabaynta; Turret-ka duurka ah wuxuu fududeeyaa qaab-dhismeedka turret si loo kordhiyo nolosha adeegga; qalabaynta dheer ayaa loo isticmaali karaa si loo kordhiyo saxsanaanta hagida loona balaadhiyo nolosha adeega qalabaynta (ee xaashi qaro weyn).

3. Soo dejinta pneumatic, saliidaynta iyo qaybaha korantada waxay xaqiijiyaan kalsoonida mashiinka oo dhan.

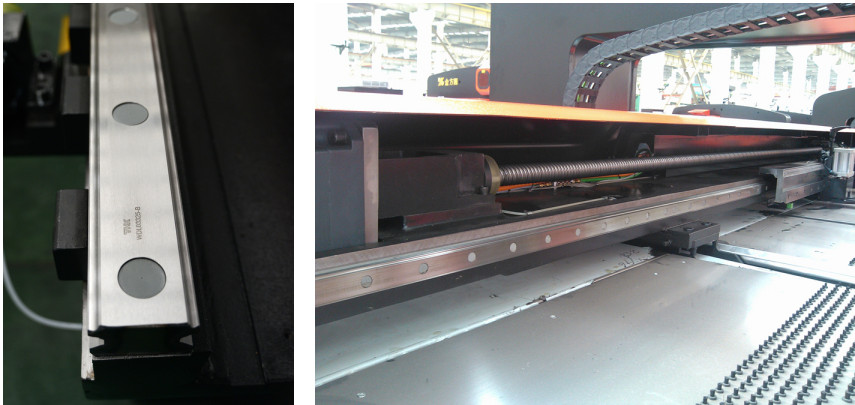

4. Dariiqa hogaanka wayn iyo kubbada laga keenay Japan ama Germany waxay hubisaa quudinta sare ee saxda ah.

5. burush adag iyo kubbad isku qasan miiska shaqada waxay yaraynaysaa qaylada iyo gariirka inta lagu jiro orodka waxayna sidoo kale ilaalisaa dusha xaashida.

6. Qaabka alxanka leh ee nooca O-ga ayaa la gariiray laba jeer, walbahaarkana gebi ahaanba waa la tirtiray. Qaabka waxa farsameeyay Jarmalka SHW xarunta wax qabad ee pentahedron-dual-side hal mar, looma baahna in la sameeyo meelaynta mar labaad.

7. Isku-xidhka sabbaynaya oo leh xoog cufan oo weyn ayaa hubisa quudinta xasilloon; gaadiidka isku dhafan ayaa hubinaya qallafsanaanta wanaagsan iyo dhaqdhaqaaqa ku habboon ee xajinta.

8. Nidaamka waxaa lagu soo bandhigay shaqada ilaalinta si toos ah si looga fogaado waxyeelada qalabka iyo xiritaanka, hubinta socodsiinta joogtada ah ee barnaamijka.

9. Auto-index-ka wuxuu qaataa giraangiraha gooryaanka saxda ah ee saxda ah iyo habka dixiriga, isagoo hubinaya tusmaynta saxda ah ee sare. Max. dhexroor qalabaynta gaari kartaa 88.9mm iyo auto-index waa la ballaarin karaa ilaa 4 nos.

10. Qaab-dhismeedka bim ee isku-dhafan si loo sameeyo qaadista iyo laydhka hal qayb, kordhinta qallafsanaanta waxayna keenaysaa meelaynta saxda ah. Mashiinku wuxuu u shaqayn karaa si xasiloon inta lagu jiro quudinta xawaaraha sare waxayna soo afjaraysaa leexinta faasasyada X iyo Y.

11. dhidibka X: wuxuu qaataa servo motor si uu u kaxeeyo kooxda kubbadaha saxda ah ee saxda ah iyo gaadhiga waxaa lagu soo bandhigay qallafsanaan sare iyo naqshad khafiif ah. dhidibka Y: matoorka servo wuxuu si toos ah u wadaa raafka quudinta kaas oo ku xidhan mashiinada hagaha, nooca kala go'a waxaa lagu hagaajiyaa shalef quudin, iyo awooda ku simaha waxaa loo gudbin doonaa mashiinka mashiinka & dhulka iyada oo loo marayo rack quudinta iyo hagaha si loo yareeyo is gariirka iftiinka. Qaab dhismeedkan waxaa lagu soo bandhigay astaamaha qallafsanaanta wanaagsan, miisaanka khafiifka ah, cufnaanta hooseeya, iyo jawaabta firfircoon ee wanaagsan ee nidaamka quudinta oo dhan, orod xasilloon iyo saxsanaan wanaagsan.

12. Nidaamka saliidda dhexe ayaa la qaatay si loogu diro dufanka saliidda si toos ah barta saliidda qaraabada, hoos u dhigista khilaafka lammaane kasta oo shaqeeya iyo kordhinta nolosha adeegga.

13. Beddelka ka-hortagga xaashida-qallooca iyo beddelka xaashi-ka-hortagga-xariifnimada waa la qaatay.

| Maya | Magaca | Qty. | Odhaah |

| 1 | Liiska Xidhmada | 1 set | |

| 2 | Shahaadada Tayada | 1 set | |

| 3 | Buugga Hawlaha Makaanigga | 1 set | |

| 4 | Buugga Hawlaha Korontada | 1 set | |

| 5 | Sawirka aasaaska | 1 set | |

| 6 | Sawirka Maamulaha Korontada | 1 set | |

| 7 | Dukumeentiyada Nidaamka Software-ka-Barnaamijka | 1 set | |

| 8 | Sawirka Maamulaha Korontada ee DBN | 1 set | |

| 9 | Buug-gacmeedka qalabka | 1 set | |

| 10 | Buugga nidaamka CNC | 1 set | |

| 11 | Sawirka Qalabka | 1 set |

| Maya | Magaca | Qiyaas | Qty. |

| 1 | Dual-head Spanner | 5.5×7-22×24 | 1 set |

| 2 | Spanner la dhaqaajin karo | 200 | 1 maya. |

| 3 | Socket Head Spanner | S1.5-S10 | 1 set |

| 4 | Kaashawiito gudub | 100×6 | 1 maya. |

| 5 | Qoriga Dufan | HS87-4Q | 1 maya. |

| 6 | Qoryaha Dufanka Dufanka Ku Duubsiiya | SJD-50Z | 1 maya. |

| 7 | Qoriga cadaadiska sare | 1 set | |

| 8 | buro qaabka T | M14×1.5 | 1 maya. |

| 9 | Bedelka u dhow | M12 PNP SN=2 furan | 1 set |

| 10 | Bedelka u dhow | M12 PNP SN=2 xidh | 1 maya. |

| 11 | Spanner | T09-02,500,000-38 | 1 maya. |

| 12 | Spanner ee gaaska dhululubada shido | 1 set | |

| 13 | Dhuumaha jilicsan | Ø 12 | 1 maya. |

| 14 | biin tuubada jilicsan | KQ2H12-03AS | 1 set |

| 15 | Qaybaha aasaaska | 1 maya. |

| Maya | Magaca | Qiyaas | Qty. | Odhaah |

| 1 | Looxa qalabka xajin | 3 no. | T02-20A.000.000-10C T02-20A.000.000-24A | |

| Qabso looxa xamaaliga | 6 no. | T02-20A.000.000-09C Ama T02-20A.000.000-23A | ||

| 2 | Guga Qalab yar oo xajin ah | M4x10 | 20 no. | T02-06,001,000-02 |

| M5x12 | ||||

| 3 | maroojiska isku xidhka gudaha | M8 x 1 x 20 | 20 maya. | |

| 4 | daab xiiraya | 30T | 2 no. | T09-16.310,000-0.1.2 |

| 5 | Isku dhufashada gudaha | M8 x 1 x 20 | 4 no. |

Nidaamka FANUC CNC waa nidaamka khaaska ah ee CNC ee ay soo saartay Japan FANUC gaar ahaan ujeedada la kulanka sifooyinka mashiinka noocan ah, hagaajinta kalsoonida mashiinka ilaa xad.

I, Tilmaamaha Nidaamyada

1. Sawirka iyo shaqada feerka;

2. Ku habboon barnaamijka koodhka caalamiga ah ee G oo loogu talagalay hawl fudud;

3. Universal RS232 dekedda caadiga ah si ay ula xiriiraan kombiyuutarka si ku habboon;

4. Nidaam buuxa oo dhijitaal ah oo servo motor iyo servo;

5.10.4 ″ LCD muuqaal midab leh;

6. Celceliska garaaca garaaca semi-loop;

7. Xusuusta EMS: 256K;

8. Barnaamijka goobta, barnaamijka xafiiska;

9. Bandhig Shiinaha iyo Ingiriisi;

10. Shaqada jilitaanka garaafyada;

11.Hal kaarka PCMCIA oo baaxad weyn oo loogu talagalay kaydinta halbeegga nidaamka, sawirida jaranjarada iyo barnaamijka habaynta, iyo xaqiijinta habka online-ka ah ee barnaamijka farsamaynta awoodda;

12. Kordhinta cutubka ugu yar, kontoroolka servo ogaanshaha booska si loo xaqiijiyo xawaaraha sare iyo hawlgalka saxda ah ee sare;

13. Badhanka hawlgalka ee guddida waxaa lagu qeexi karaa si waafaqsan shuruudaha dhabta ah;

14. Xadhigyada xogta xajinta xawaaraha sare ee sare oo leh xiriir yar oo fiilada;

15. Isdhexgalka sare, software gaar ah. Waqtiga gaaban ee bilawga ah, xogtu ma lumin doonto haddii korontadu ay si lama filaan ah u yaraato;

16. Kaydinta 400 oo qaybood oo barnaamij ah.

1. Faasas toosan: X, faashas Y, faashas wareeg ah: T, faashash C, dhidibka feerka: dhidibka Z;

2. Alaarmiga qaladka korontada sida istaroogga xad dhaafka ah.

3. Shaqada is-baaridda.

4. Shaqada xadka jilicsan.

5. Universal G code ee barnaamijka;

6. Shaqada magdhowga qalabaynta;

7. Shaqada magdhowga masaafada iswiidhishka;

8. Shaqada magdhowga gaabska ah;

9. leexashada shaqada iskuduwayaasha;

10. Shaqada dib u dhigista;

11. Shaqada AUTO, BUUGGA, qaabka JOG;

12. Shaqada ilaalinta xajinta;

13. Shaqada qufulka diiwaanka gudaha;

14. Shaqada barnaamijka cabbirka;

15. Shaqada barnaamij-hoosaadka;

16. Shaqada meelaynta degdega ah iyo qufulka feedhaha;

18. Shaqada M code;

19. Barnaamij buuxa iyo kordhin;

20. Bood qaboojiye, aan shuruud lahayn.

Soo bandhigida barnaamijka barnaamijka

Waxaan ka qaadanay CNCKAD Shirkadda METALIX. Software-ku waa barnaamij dhammaystiran oo CAD/CAM ah oo si toos ah barnaamijka u samayn kara min nakhshad ilaa wax soo saar. Iyada oo la adeegsanayo maamulka maktabadda caaryada, habaynta habka xulashada tooska ah, hagaajinta waddada iyo hawlaha kale, waxaa si toos ah u soo saari kara CAD sawirada NC hababka habsocodka. Waxaad ku guuleysan kartaa hal barnaamij oo hal qayb ah, buul toos ah iyo xirmo dhammaystiran.

Function of DrawingCNCKAD garaafyo awood leh, fudud oo dareen leh in la isticmaalo, marka lagu daro shaqada sawirka caadiga ah si waafaqsan sifooyinka xaashida xaashida, ku daray qaar ka mid ah hababka sawir gaar ah sida jeexida, wareega, saddexagalka, xagal saxda ah iyo qaab kontoroolka, cajiin, hubin tafatirka iyo sixitaan toos ah, goynta ama shaabadeynta, characters Chinese input DXF/IGES/CADL/.DWG file iwm

b) Shaqada feerka

Lagu sifeeyay feedh toos ah, caaryo gaar ah, tilmaame toos ah, guuritaan toos ah, goynta cidhifyada, iyo hawlo kale.

c) Shaqada Shearing

Si otomaatig ah u hubi koontaroolka oo sax xuduudaha nooca maaddada, dhumucda, gooyn hal, gooyn, raritaan xiirid, iyo hawlo kale, saxanka fulinta habaynta tooska ah ee xiirashada.

d) Processing ka dib

Habayn toos ah ama is dhexgal ah ayaa daboolaysa dhammaan geeddi-socodka: shaabadeynta, laysarka, balaasmaha, dabka, goynta biyaha iyo wax-shiidka.

Habaynta sare ee boostada waxay soo saari kartaa dhammaan noocyada koodhka NC ee waxtarka leh, taageerada subbroutine, barnaamijka macro, sida hagaajinta dariiqa qalabka iyo wareegga ugu yar ee caaryada, duritaanka taageerada, mashiinka nuugista vacuum sida walxaha iyo heerka xannibaadda.

Barnaamijka u wareejinta mishiin kale kaliya waxay u baahan yihiin dhawr gujis oo jiirka ah.Kuwaani waxay ka soo jeedaan habka CNCKAD post processing, iyadoo meesha laga saarayo faylalka kombuyuutarrada ee xad-dhaafka ah kuwaas oo hawlgalka ka dhigaya mid aad u wanaagsan.

e) Jilidda garaafka ee CNC

Software-ku wuxuu taageeraa jilid kasta oo garaaf ah oo barnaamijka CNC ah, oo ay ku jiraan koodka CNC-ga gacanta lagu qoray, habka tafatirka sidoo kale waa mid aad u fudud, softiweerku wuxuu si toos ah u hubin karaa khaladaadka, sida cabbirada lumay isku dhejinta iyo khaladaadka fogaanta, iwm.

f) Ka beddelka NC una beddelo Sawir

Gacan qoraal ah ama kood kale oo NC ah, waxaa si fudud loogu rogi karaa qaybo garaafyo ah.

g) Taariikhda Warbixinta

Daabici kara warbixinta xogta, oo ay ku jiraan dhammaan macluumaadka sida tirada qaybaha, habaynta macluumaadka sida wakhtiga, caaryada dhigay iwm.

h) Gudbinta DNC

Qaadashada interface-ka Windows ee moduleka gudbinta, si isu-gudbinta u dhexeysa PC iyo qalabka mashiinka ay tahay mid aad u fudud.

1) Taageero dhammaan noocyada hadda jira ee CNC turret feerka, mashiinka goynta laser, mashiinka goynta plasma iyo mashiinka goynta ololka iyo qalabka kale ee mashiinka.

2) Taageero habka oo dhan ee hawlgalka qalabka CNC ah, oo ay ku jiraan sawir, si toos ah ama processing is-dhexgalka, post processing, barnaamijka jilitaanka CNC, gacanta iyo goynta si toos ah, NC file download iyo upload iwm.

3) Waxay si toos ah u gelin kartaa Autocad, SolidEdge, SolidWork iyo CadKey iwm oo ay ku jiraan dhammaan faylasha garaafyada ee software-ka caanka ah ee CAD.

4) 、Software taageertaa noocyo kala duwan oo ka mid ah qalabka gacanta tiro kala duwan, gelin karaa qaybo NC a dhalin files qalab kala duwan, waayo, qalab kala duwan waqti isku mid ah inta lagu guda jiro processing.

Dib u dejin toos ah

Marka cabbirka saxanku uu ka weyn yahay tiro cayiman, mishiinku si toos ah ayuu dib u dhigayaa, ka dibna si toos ah u soo saaray tilmaamaha meelaynta; Haddii isticmaaluhu uu leeyahay shuruudo gaar ah, waa la beddeli karaa ama la tirtiri karaa tilmaamaha meelaynta re.

Ka fogaanshaha isku dhejinta tooska ah

Tilmaamaha loo soo saaray si toos ah meelaynta taasoo ka dhigi karta isku-xidhka inay ka fogaato aagga dhintay, yaraynta qashinka; haddii saxanku yahay qayb ama qaybo badan oo saxan bir ah, waxay xaqiijin kartaa hawlgalka ka fogaanshaha isku xidhka.

Qalabaynta alaabta

Si loo yareeyo qallafsanaanta walxaha ku jira geeddi-socodka shaambaynta, farsamada wax-soo-saarka walxaha faleebada ayaa la qaadan karaa, iyo qalabka wax lagu gooyo waxaa loo isticmaali karaa xagga hore ama xagga dambe ee tilmaamaha laanta.

Farsamada jaridda

Marka lagu daro shaqada feerka cidhifka caadiga ah, feerka tooska ah kaas oo awood u leh inuu feero walxaha jaban ee ku wareegsan cidhifka.

Degenaansho kali ahi si toos ah ayay u socotaa

Mashiinka xajin kara ee la dhaqaajin karo waxaa soo saari kara software-ku si toos ah ugu dhaqaaqa xajinta iyadoo la raacayo tilmaamaha NC.

Wareegga dhimasha ugu yar

Doorashada wareega ugu yar ee dhimashadu waxay yarayn kartaa xidhashada rugta tusmaynta tooska ah waxayna wanaajin kartaa waxtarka wax soo saarka.

Shaqada Noocyo Feedh badan

Shaqada feerka saddexagalka, feerka garoorka, feerka qaansada iyo hababka kale ee feerka waxtarka leh.

Shaqada Feer-Furista Xoog leh

Astaamaha feerka tooska ah waxaa ka mid ah isku xirka yar yar ee otomaatigga ah, xulashada caqliga leh ee caaryada iyo hanti ogaanshaha alaarmiga iyo hawlo kale.

I) Shaqada goynta tooska ah

METALIX CNCKAD waxa ku jira qayb AutoNest ah kaas oo ah set saxan dhab ah oo toos ah software buul hagaajinta, kaas oo xaqiijin kara dhammaan hagaajinta birta ee habka farsamada.

1. Qalabka hawada: cadaadiska shaqada ee lagu qiimeeyay waa inuu ka badan yahay 0.6mPa, socodka hawada: in ka badan 0.3m3 / min

2. Awoodda: 380V, 50HZ, isbedbeddelka korantada: ± 5%, awoodda korantada ee 30T waa 45KVA, dhexroorka fiilada firfircooni waa 25mm², jabiye waa 100A. Haddii korontadu aysan xasilloonayn, xasiliyaha ayaa loo baahan yahay, haddii ay jirto koronto-baxa, ilaalinta ayaa loo baahan yahay.

3.Hydraulic oil: (SHELL) Tonna T220, Ama saliid kale oo hagaha iyo saliidaynta tareenka.

Saliidda saliidda: 00#-0 # dufan cadaadis daran (GB7323-94), soo jeedin: ka hooseeya 20 ° C isticmaal 00 # dufan cadaadis daran, oo ka sarreeya 21 ° C isticmaal 0 # dufan cadaadis daran

| Summada | Magaca | Hadallo | Heerkulka |

| Shell | EPO | 0# Dufan cadaadis daran | 21°C ka sareeyo |

| Shell | GL00 | 00# Dufan cadaadis daran | 20°C ka hooseeya |

3. Heerkulka deegaanka: 0°C - +40°C

4. Qoyaanka deegaanka: qoyaan qaraabo ah 20-80% RH(aan-condensation)

5. Ka fogow gariirka xooggan ama faragelinta elektromagnetismka

6. Deegaanka oo boodh yar leh, oo aan lahayn gaas sun ah

7. Diyaari shaqada aasaasiga ah si waafaqsan sawirka aasaasiga ah

8. Isticmaaluhu waa in uu u xushaa farsamayaqaanka ama injineerka tababarka, kaas oo taariikhdiisa waxbarasho uu ugu yaraan ka qalin jabiyay dugsiga sare ee farsamada, una habeeyo muddo dheer.

11.Waa inuu diyaariyaa aasaaska sida ku cad sawirka

12. Furan furka 65mm spanner, ul kaalmeeya gubashada dambe, si loo hagaajiyo heerka aasaaska.

13. In ka badan 5 litir oo shidaal nadiif ah, tiro calal ah, qori, saliid saliid ah, ilaa 1 litir oo ah qalabka wax lagu xoqo iyo caaryada.

14 oo leh hal Ф10 * 300 iyo hal Ф16 * 300 ulo naxaas ah oo loogu talagalay rakibidda caaryada. Dhuxul dheer (fiyuusyada iyo alwaaxdu si gooni ah ayaa loo baakadeeyay, laakiin sidoo kale si loo diyaariyo cutubyada la raray)

15 tilmaame garaac (0-10mm kala duwan), oo loo isticmaalo in lagu saxo dhidibka X iyo Y.

16 marka qalabku gaaro warshadda, diyaari taraafikada 20T ama wiishashka qalabka qaadista

17.If dhidibka V waxaa lagu qalabeeyaa matoorka qaboojiyaha biyaha, dhexdhexaadiyaha qaboojinta ee la xidhiidha waa in la diyaariyaa, mugga waa 38L

Arrimaha kale ee aan la daboolin waxay u baahan yihiin tafsiir iyo isuduwid dheeraad ah

CNC Turret Punch Machine; Turret Punch Machine; Turret Punch Machine Mashiinka feerka; Mashiinka feerka iyo foorarsiga cnc

| Maya | Tilmaamid | Unug | Qaabka Mashiinka | ||

| MT300E | |||||

| 1 | Max. Ciidanka Punch | kN | 300 | ||

| 2 | Nooca Wadista ugu Weyn | / | Hal mooto wada | ||

| 3 | Nidaamka CNC | / | FANUC CNC nidaamka | ||

| 4 | Max. Cabbirka Habaynta xaashida | mm | 1250*5000 (oo leh hal meel oo kale) | 1500*5000 (oo leh hal boos | |

| 5 | No. of Clamp | maya | 3 | ||

| 6 | Max. Dhumucda xaashida habaynta | mm | 3.2/6.35 | ||

| 7 | Max. Dhexroorka Punch per Time | mm | Φ88.9 | ||

| 8 | Faaliga ugu weyn | mm | 32 | ||

| 9 | Max. Ku dhufo xawliga 1mm | hpm | 780 | ||

| 10 | Max. Punch Hot at 25mm Pace | hpm | 400 | ||

| 11 | Max. Xawaaraha Nibbling | hpm | 1800 | ||

| 12 | No. ee Dib u dhigista Silinder | dhigay | 2 | ||

| 13 | Lambarka Saldhigga | maya | 32 | ||

| 14 | Tirada AI | maya | 2 | ||

| 15 | Tirada Xakamaynta dhidibka | maya | 5 (X, Y, V, T, C) | ||

| 16 | Nooca Qalabka | / | Nooca Dheer | ||

| 17 | Nooca Shaqada | / | Ka hooseeya 3.2mm: burush buuxa oo go'an miiska shaqada (Kubadaha kor u qaadida rarida waxaa lagu dari karaa ikhtiyaar ahaan) | ||

| Ka sarreeya 3.2mm: Kubadaha buuxa waxay shaqayn karaan | |||||

| 18 | Max. Xawaaraha quudinta | X dhidibka | m/min | 80 | |

| Y dhidibka | 60 | ||||

| XY Isku darka | 100 | ||||

| 19 | Xawaaraha Turret | rpm | 30 | ||

| 20 | Xawaaraha Wareega Qalabka | rpm | 60 | ||

| 21 | Saxnaanta | mm | ±0.1 | ||

| 22 | Max. Awoodda Xamuulka | Kg | 100/150 oo loogu talagalay kubbadda shaqada | ||

| 23 | Awoodda Matoorka ugu weyn | kVA | 45 | ||

| 24 | Habka qalabaynta | / | nooca degdega ah ee madax banaan | ||

| 25 | Cadaadiska Hawada | MPa | 0.55 | ||

| 26 | Isticmaalka Hawada | L/ daq | 250 | ||

| 27 | Awoodda xusuusta CNC | / | 512k | ||

| 28 | Ku dheji ogaanshaha aagga dhintay | / | Y | ||

| 29 | Sheet-ka-hortagga-xariifnimada Wareegga | / | Y | ||

| 30 | Ka-hortagga xaashida-qallafsanaanta | / | Y | ||

| 31 | Qiyaasta dulucda | mm | 5350×5200×2360 | 5850×5200×2360 | |

| Maya | Magaca | Summada | Qiyaas | ||

| 1 | Nidaamka CNC | FANUC | OI-PF | ||

| 2 | Servo Driver | FANUC | AISV | ||

| 3 | Servo Motor ( dhidibka X/Y/C/T) | FANUC | AIS (X, Y, T, C) Matoorka gaarka ah ee dhidibka V | ||

| 4 | Jidka hage | THK | HSR35A6SSC0+4200L (X:2500) | ||

| HSR35A3SSC1+2060L-Ⅱ (Y:1250) | |||||

| HSR35A3SSC1+2310L-Ⅱ (Y:1500) | |||||

| 5 | Ballscrew | THK | BLK4040-3.6G0+3016LC7 (X:2500) | ||

| BLK3232-7.2ZZ+1735LC7T (Y:1250) | |||||

| BLK3232-7.2ZZ+1985LC7T (Y:1500) | |||||

| 6 | Saamaynta Saxda ah | NSK/Koyo | 25TAC62BDFC10PN7B/SAC2562BDFMGP4Z | ||

| 30TAC62BDFC10PN7B/SAC3062BDFMGP4Z | |||||

| 7 | Qaybaha pneumatic | Saddex-wadajir | SMC | AC30A-03D | |

| Solenoid valve | SY5120-5D-01 | ||||

| Muffler | AN10-01 | ||||

| Silinder | CP96SDB40-80-A93L | ||||

| 8 | Nidaamka Korontada | jabiye | Schneider | / | |

| Xiriir | Schneider | / | |||